Mimaki's TxF150-75 is a highly acclaimed DTF (Direct To Film) printer used for printing on apparel like T-shirts. We'll explain its features and case studies in an accessible way.

Are you thinking about any of these things?

Want to learn more about DTF, the latest T-shirt printing method?

Want to know why Mimaki's TxF150-75 is chosen among DTF printers?

Want to offer customers T-shirts and bags designed and printed on the spot?

->The TxF150-75 meets those needs!

What is DTF, the Latest Apparel Printing Method?

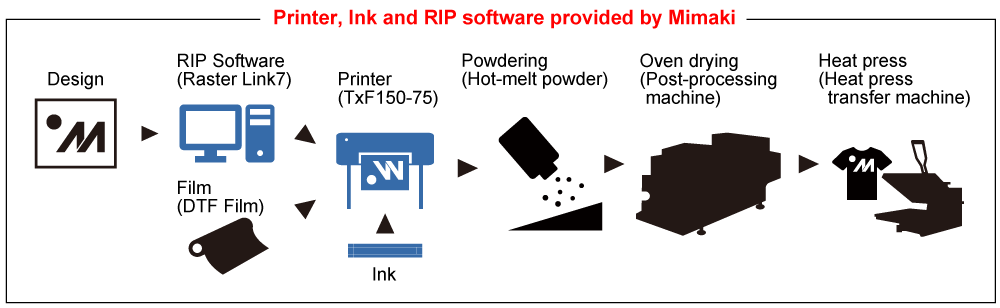

Print the design directly onto specialized transfer film using a printer.

Next, sprinkle a powder called hot melt powder onto the printed film, then apply heat to dry it, forming a layer of transferable ink on the film.

Transfer this formed ink layer onto fabric such as T-shirts using a heat press, completing the finished product on the spot.

You can view the process in a video.

DTF printers, rapidly gaining adoption in recent years

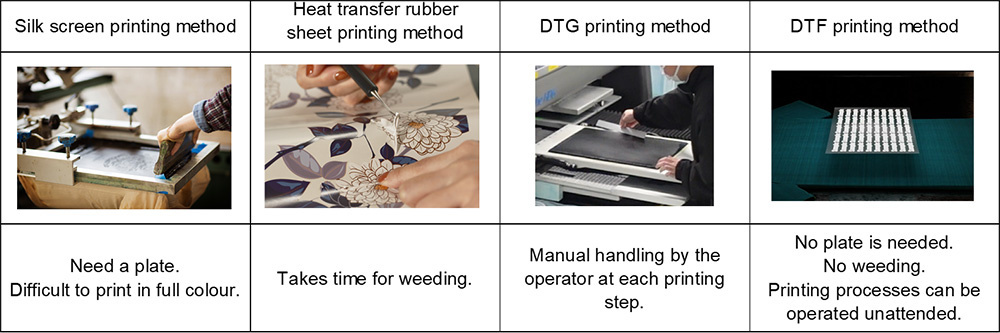

Currently, silk screen printing is widely adopted in the apparel printing market. However, this printing method requires preparing screens, making it unsuitable for small-lot production. Full-color printing is labor-intensive and necessitates creating a separate screen for each color used.

Additionally, heat transfer methods using rubber sheets are also common. However, when fixing the printed transfer sheet to the fabric, manual labor is required for the “shavings removal” process to remove the unused parts of the transfer.

In recent years, DTG (Direct To Garment) printing, which uses inkjet printers to print designs directly onto clothing or fabric, has also become widespread. DTG printing eliminates the need for screens and supports full-color printing, but it requires fabric pretreatment and involves manual operator intervention at each printing stage.

DTF printing eliminates the need for screens and shavings removal, which were challenges in conventional printing methods. Since the printing process can be unmanned, it is rapidly being adopted in the market as a labor-saving technology.

A single DTF printing system can print on a variety of materials.

Not just for T-shirts, but also for printing on tote bags and jackets.

Compatible with various materials including cotton, polyester, and nylon.

Key features of Mimaki's DTF printer, the TxF150-75

- Stable white ink operation enables vivid printing of designs onto colored T-shirts.

- Equipped with automatic nozzle clog detection and recovery functions for printheads. Continue printing without waiting for service engineer repairs.

- ECO PASSPORT certified ink to ensure customer safety and security.

Machine size

The machine fits within approximately 2×1 meters (3.3×6.6 feet).

Its compact size makes it suitable for installation even in offices or retail spaces with limited space.

Customer Reviews After Implementation

Wide Design Co., Ltd.

Every day, we receive the same specifications, and I sometimes doubt my eyes, thinking it must be a mistake (lol).

That's how incredible the volume of repeat orders is.

I'm delighted that everyone highly appreciates the excellent finishing quality.

High Usability and Stable Operation as Key Factors for Adoption: Wide Design Co., Ltd. | Mimaki user stories | Case Study

Delivering a New Customer Experience with Secure, Stable, and Simple Operations

The TxF150-75 has received enthusiastic feedback from many customers.

The reliable and stable DTF printer, TxF150-75, enables apparel shops and design offices to easily provide printed T-shirts directly to customers.

It can print limited designs or customer-provided designs starting from just one item, creating an unprecedented customer experience.

Please visit your nearest showroom or sales office to see the TxF150-75 in person.

EDP Awards 2024 Winner: "Best Textile Printer Direct to Transfer"

The TxF150-75 was recognized by the European Digital Press Association (EDP) as the "Best Textile Printer Direct to Transfer," praised for its stable operation.

Learn more here. *Mimaki Global News

Product Introduction Process & Contact Us

The TxF150-75 can be viewed and sample production performed at Mimaki Engineering sales offices and distributors worldwide.

Please feel free to contact us for visit, quotes, information on cost-effective purchasing methods, or any other inquiries, please apply via the inquiry form at the bottom of this page.

Please note: Mimaki offerings for DTF printing will be printers, inks and RIP software. Our recommended specifications for the film used to create the transfer sheet, hot-melt powder, powder application equipment, post-processing machines and heat press transfer machines are provided to customers at the time of sale.