A case study of Kinko's Japan Co., Ltd. which has installed the JV330-160, was published in the sign industry magazine “Kanbankeiei” , Vol. 34 (August 2024 issue).

The following is the published article in its original form.

Sign business that can only be entrusted to JV330, White ink that major on-demand print service providers have absolute confidence in.

- Combines exceptional high density and output speed -

Kinko's Japan is a leading on-demand print service provider. In recent years, Kinko's has been gaining recognition from users for its business development focusing on sustainability management, and since September 2021, the company has adopted "PELP!", a recycling service that upcycles unneeded copy paper into 100% recycled paper. In addition to switching its own business cards and envelopes, the company also handles printing services for its customers as an eco-commercial product. In the same year, the company also renewed its staff uniforms. Instead of disposing of used clothes, they created promotional materials that were chemically recycled as raw materials for paper. In May 2023, all directly-managed stores and production sites will be certified by the international forest management council, FSC®, as CoC-certified for the processing and distribution process, and they will continue to pursue sustainability without waste because of our one-of-a-kind on-demand products.

In addition, the company is also focusing on initiatives for regional co-creation. In November 2023, in cooperation with local companies in Ishikawa Prefecture, the company established a paper recycling model based on local production for local consumption. This recycled paper is named "Okiagami," derived from the traditional craft Kaga Hachiman Okiagari, and a portion of its sales is currently being donated to the Noto Peninsula Earthquake Relief Fund. In February 2024, the company and Kawasaki Frontale, a professional soccer club, launched an initiative to reuse acrylic partitions no longer needed by local restaurants and other establishments. The company will also maintain its commitment to becoming a partner of the communities in which it operates and contributing to the development of local communities by holding workshops at home games that creating goods using scrap acrylics.

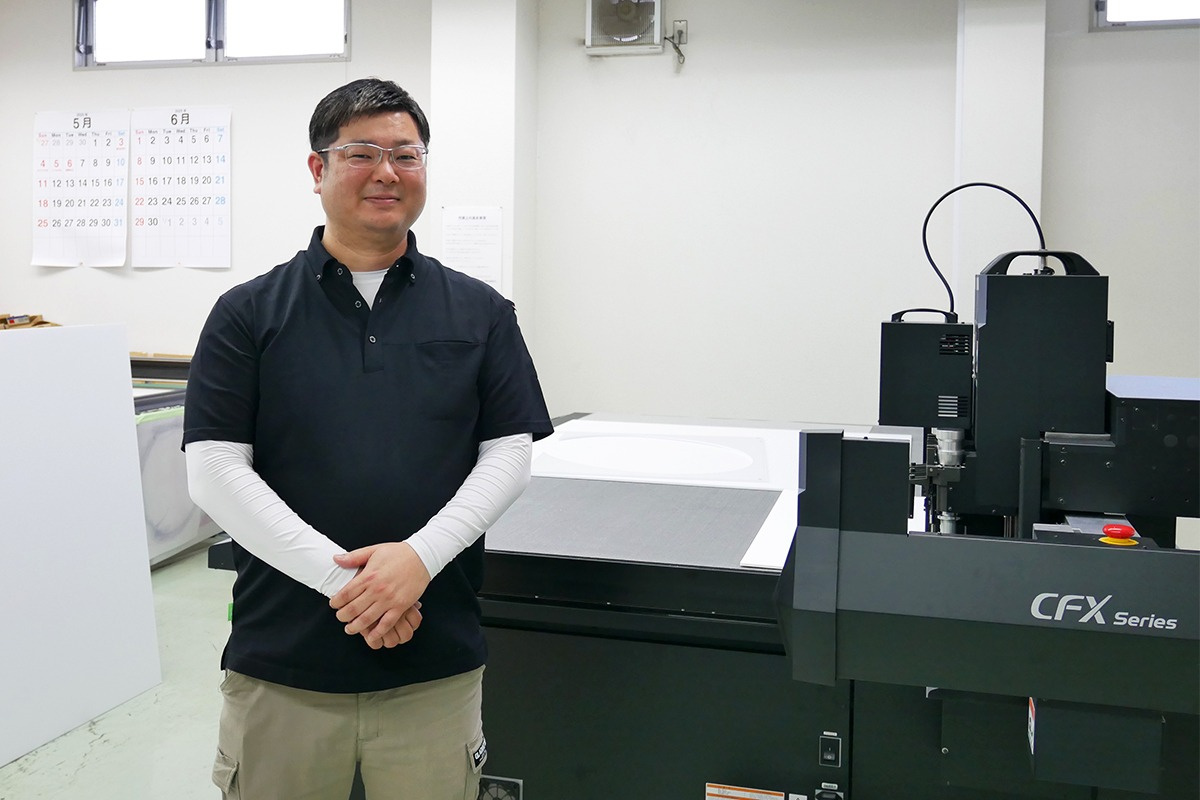

The sign business was launched in earnest with the launch of the Sign&Display division in 2013. In April 2018, the company consolidated its production facilities into the Tokyo Secured Production Center (SPC), located in Shinagawa, Tokyo. The center is equipped with a full range of roll and flatbed printers, including 11 Eco-Solvent, water-based, and UV printers. The post-processing equipment is also a centralized production facility that encompasses not only laminators and plotters, but also sample cutters and laser processing machines. Furthermore, in April 2019, the company integrated Interlink, a Tokyo-based output vendor whose strength lies in providing a one-stop service from planning to installation, to put its service system on a firm footing.

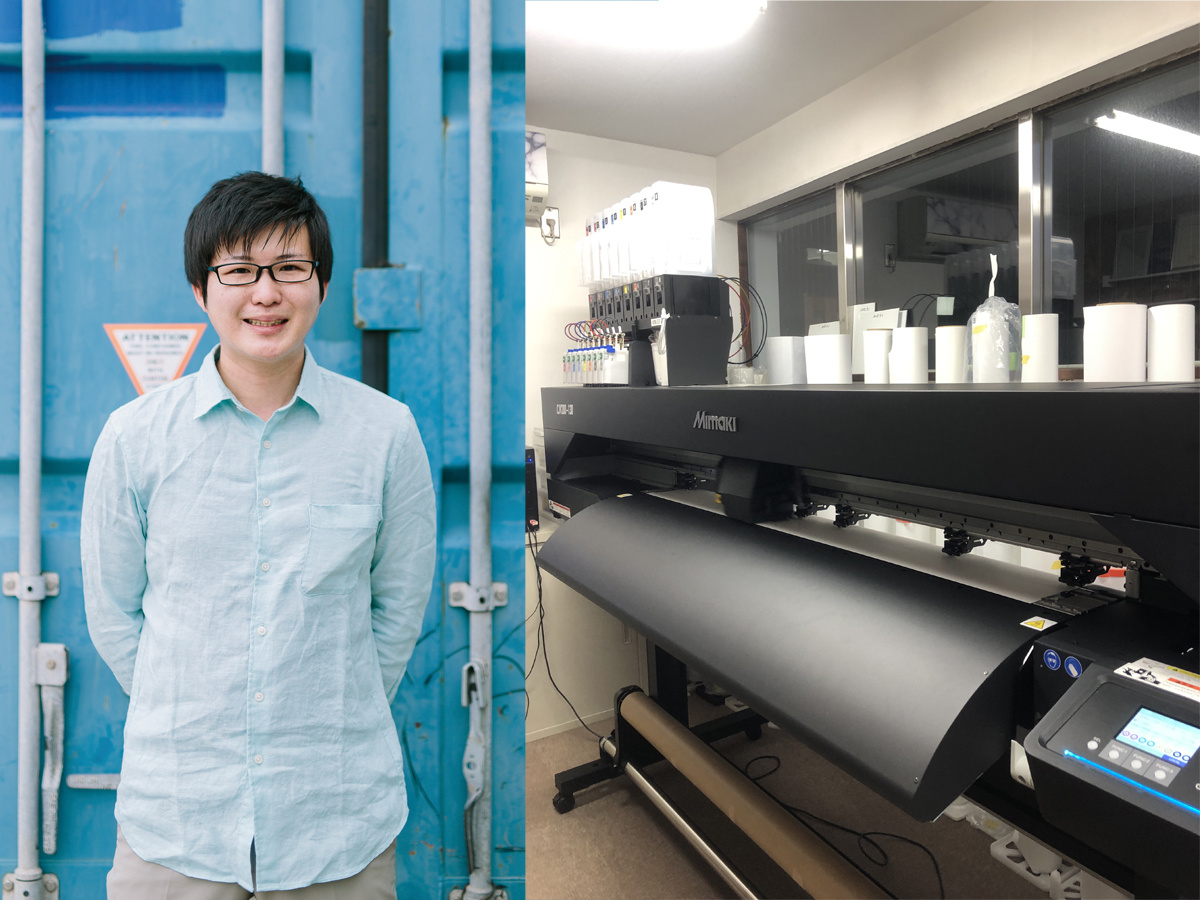

Then, in August 2023, Mimaki's flagship model, the JV330-160, was introduced, creating a more seamless production system. We will now talk to Yoshitaka Muroya, in charge of SPC division, about why the company newly installed the JV330 while possessing such a large amount of equipment.

Yoshitaka Muroya, SPC Manager, Tokyo Production No. 2, SPC Production Control Group, Production Control Dept.

"Kinko-chan" was appointed as the official character in June 2024.

— First of all, how long have you been dealing with Mimaki?

That was from the launch of the Sign&Display division. It has been more than 10 years since we made our first capital investment in a flatbed UV machine, the JFX500-2131. I still think that Mimaki is by far the best in terms of output speed and density with white ink, which I have appreciated since those days. As well as its machine specifications, it has a very good support system, so I am happy to be able to operate with peace of mind. Although we now have a large number of printers, we started with three printers at the beginning and the loss when even one of them stopped is immeasurable. We have been helped many times in the past by the quick response time, when we have a small problem, they come to us as soon as we contact them.

— I see that you have had a long relationship with Mimaki since the establishment of the division. Then, please tell us why you introduced the JV330-160 at this time.

To be honest, when I visited the showroom to select a model due to the aging of the JV300, the stylish chassis of the JV330 was the first thing that caught my eye. I simply thought it was very cool. I have seen countless models, but I have never seen such a non-angular design, and I was impressed by the attention to detail that went into its development. As a flagship model that combines high image quality and high production, there is naturally no doubt about its excellent specifications. I could sense the strong enthusiasm that went into the development and release of this machine, and I am convinced that the potential of this machine is greater than I had imagined.

— That's an interesting point of view. Certainly, we can read the seriousness of the manufacturer from such a point. How about the specific performance of JV330?

The aforementioned white ink print speed and high density are not only firmly inherited, but have certainly evolved. Compared to other companies' machines, I can say that it is now a step ahead. That is to say, when color is layered after white underpainting on transparent media, we are amazed at the clear and crisp finish, despite the fact that the output speed is more than twice as fast as before. Currently, I am printing with JV330 at 16pass instead of the conventional 12pass, but the speed has not decreased at all. The output is naturally more beautiful than before, and this has led to an improvement in the quality of our company.

In addition, the JV330 outputs a wide variety of media, including transparent PVC, PET, and synthetic paper, so for this reason we are making full use of the new media changer function. It is revolutionary to be able to change media so easily by simply spinning it around without any effort. The ability to easily switch from one roll to the next dramatically increases productivity, especially for large-lot projects. Other than that, the machine is very resistant to static electricity, and I am afraid to output anything other than JV330 for light-shielding synthetic paper.

Furthermore, while the UCJV300 and JFX500/200 are also in operation, it is helpful that they all have the same specifications and unified feel of the actual machine and software RIP operation. The same is true for the new JV330, which I personally look forward to because it provides a relief when introducing a new machine and even adds some of easy-to-understand functions that make things even easier.

Installation scene of the new JV330

A sample of output on PET film. The density of the white ink is increased step by step from the top. While other companies' machines tend to produce a finish in the middle of the image, the JV330 produces a clear print without blurring the image as shown in the lower part of the image.

— Next, what are your plans for future capital investment?

I am very interested in the "toggle print function" of the new JFX600-2531 that I saw at the exhibition. Until now, I thought it was inevitable that a flatbed machine, unlike a roll machine, would stop running after outputting, but with this function, continuous operation can be realized. It would be attractive to be able to set the next media at the back side of the table while outputting at the front side, so we continue printing.

Considering the burden on operators, "MDL* commands" are provided to enable control of the actual machine from peripheral devices, as expected. If we can take advantage of this, we can even achieve automatic transport of media before and after output by the arm robot. We hope to boldly incorporate these new functions in the future.

*Mimaki Device Language

— Finally, what are your future prospects?

While the outlook for printed documents in general has become increasingly difficult, it has already been 11 years since we launched this division with the aim of creating a new pillar of business. During this time, we have received a great deal of support from sign production companies, and thanks to their help, we have been able to develop the division to the extent that it has raised the scale of our overall business. We would like to continue to grow steadily in cooperation with Mimaki, as well as with you, so that we can further enhance our presence in the future.

User profile

- NameKinko's Japan Co., Ltd.

- IndustryOn-demand Print Services

- AddressHead office: 27F Hamamatsu-cho Building, 1-1-1 Shibaura, Minato-ku, Tokyo

Tokyo SPC: 2F Shinagawa Seaside West Tower, 4-12-2 Higashi-Shinagawa, Shinagawa-ku, Tokyo - URLhttps://www.kinkos.co.jp/