You can easily print on materials and shapes that could not be handled before! One that will make you feel like "Let's try it first" even if it is a difficult project.

―― The Infinite Potential of the UJV300DTF-75 as told by One of Japan's Leading Power Vendors.

UV-DTF printer "UJV300DTF-75" was introduced at the Yokohama Factory in September 2025.

B&P Co.,Ltd., a comprehensive sales promotion support company, has achieved sales growth for the past four consecutive fiscal years and recorded a record high sales of more than 3.5 billion yen in fiscal 2024. Currently, in addition to the Osaka and Tokyo head offices, the company has sales offices in Nagoya, Fukuoka, and Kyoto, and will develop community-based sales activities in each area, which the company has focused on for many years. In 2021, they opened the "Yokohama Factory" as its main production base, which operates 24 hours a day. The total number of facilities owned by all bases is up to 100 printers and processing machines, and it will build a leading production system in Japan as a major output vendor.

In 2022, the company launched an order-made goods production service. In addition to conventional posters and panel sales promotion materials, the company has built a new production system for acrylic POP, novelties, and other products. The company's attitude of responding carefully to customers' requests has been praised, and the number of cases in which it receives orders for staff wear and goods as well as event decorations is increasing year by year. Over the past three years, the company has continued to invest in small UV machines, laser processing machines, and DTF printers. In September 2025, it introduced Mimaki's UV-DTF printer "UJV300DTF-75". It is closely tied to the community and can reach even the itchy parts, and it has already expanded its field of activity as an indispensable unit for strengthening the company's sales force.

Why did the company immediately decide to introduce the UJV300DTF-75, which had just been launched in the domestic market, when it was equipped with various mid-range printers for water-based pigments, solvents, UV, and latex, as well as flatbed machines from small to large size and super wide roll machines of 5m wide in all directions? From here, we will talk to Yusuke Nakamura, Executive Officer and Head of Corporate Production.

Executive Officer and Head of Corporate Production, Yusuke Nakamura.

― First, please tell us your impression of UV-DTF before the introduction of UJV300DTF-75.

I had a strong interest in UV-DTF, which has been popular overseas for a long time. First of all, the advantage is that compared to the conventional direct printing, the time to verify the compatibility of ink and material can be shortened overwhelmingly. In the first place, no one wants to take the risk of receiving materials from customers and trying to output them directly. In the case of UV-DTF, there is no need to prepare a new jig, and all you have to do is to attach the printed transfer sheet to the material. In addition, for example, it is possible for us to provide the output to customers and have them attach it themselves and evaluate the finish. Customers have different preferences for things like ink adhesion, so it's best to touch it with your own hands and let them see it.

As interest in Mimaki increased day by day, I heard that Mimaki was going to release the UV-DTF printer in Japan, so I started to examine it for its introduction. Because it is a new printing technology, I expected that not only the sense of security provided by the domestic product, but also Mimaki generous support would be a great help in using it.

― I see. So you'd been interested in UV-DTF for some time, and when Mimaki announced its domestic release, you decided to adopt it. How was the internal response?

To be honest, at the beginning, most of the sales people were not interested in the UJV300DTF-75, and everyone said, "What are you going to use it for?." So, I asked Mimaki to prepare a sample and gave it to the sales staff to put on their own cups. Then, the reaction completely changed to a surprising degree, and I laughed and said, "It's so good!"

UV-DTF becomes a printing technology that has never been seen before, so no matter how much it is explained orally, it doesn't seem to come up with an image. Even if I explain that only ink and glue remain, or that it is a sticker that does not need to remove shavings, it does not convey well. It was best to let them actually experience it, and if they did so, "I would be able to take that project with UV-DTF," and it was smoothly connected to my regular work.

After gaining the understanding of the sales staff, inquiries only increased even before the full-scale operation of the UJV300DTF-75. Just one month after the introduction of this system, we were able to receive orders without difficulty for materials that we had hesitated to use before, such as polypropylene (PP), which is difficult for ink to fix when primed, and mirrors, which tend to damage the printer head.

Various samples for in-house verification

― Seeing is believing. It has just been introduced. How do you evaluate the potential of UJV300DTF-75?

With the UJV300DTF-75, it's great that you don't have to worry about breaking or damaging even if you print on expensive materials. In addition, unlike the flatbed type, there is no limit on the height of the material and there is no need for jigs for special shapes, which I highly evaluate as unprecedented advantages. It is very reliable to be able to print without limiting the material and shape, and it comprehensively raises the level of our company's ability to deal with not only order goods but also signature related things. Even in difficult cases, the addition of this one unit makes me feel like "Let's try it first."

Furthermore, in addition to the testing that I mentioned at the beginning, I think that the style of mailing the transfer sheet after printing to the customer and having them attach it by hand on site will spread in the future. We can reduce the delivery time and cost much more than sending materials to each other, and I would like to prepare a manual on how to paste and spread awareness.

― How do you find the usability?

As a point of concern, the adhesive surface of the sheet was exposed before and after printing, so I was worried that it might get dusty, but I never had to start over from the introduction without taking any special measures. I heard from the site that it was a little difficult to set the separator to be attached after printing, but it seemed that I was able to get the hang of applying this tension evenly in a few times.

"Other than that, it can operate with the same operation feeling as the Mimaki printer that I have been familiar with so far, so I can handle it in the field almost without hesitation.

The only difference is that you stick the output on the material and peel it off. We are currently verifying the optimal timing of the peeling as our in-house know-how. As for the actual machine itself, as long as you have used the Mimaki printer even once in the past, I can say with confidence that anyone can operate it without hesitation."

― How do you rate the finish?

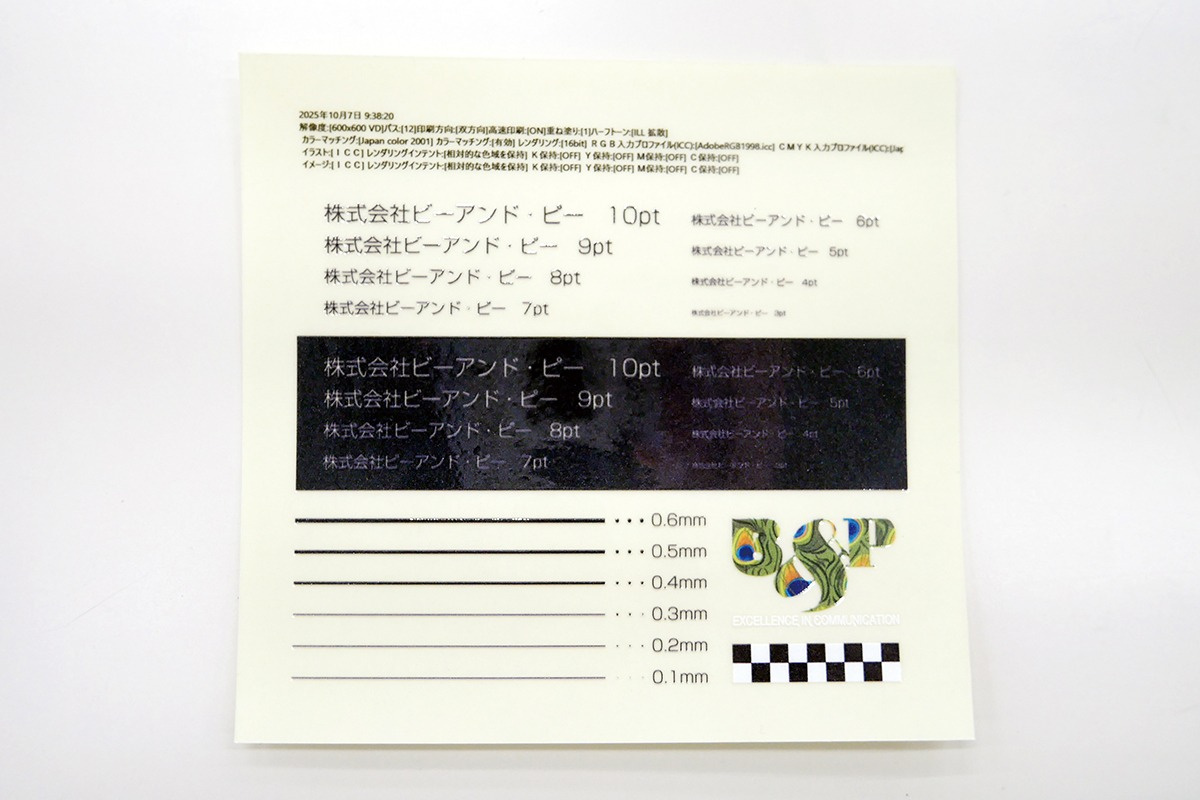

The UJV300DTF-75 is completely different from stickers and stickers in that it has no base material and only the ink and glue are fixed. Therefore, depending on the materials, there were some concerns that it might not be able to be applied cleanly or that it might not come off easily, but that was also an unfounded concern. If I give an example with easy-to-understand character size, I can decorate up to about 6pt at ease, and I feel that it is possible to finish beautifully under 4pt depending on how to use the clear ink.

It may be a geeky story, but I have an impression that Mimaki technology cultivated over many years, such as improving durability by sandwiching soft ink with hard ink, is concentrated in this one car, and as a result, an excellent finish has been realized. I have already received decorations on unusual materials such as weight scales, musical instruments, and headphones, but the evaluation from clients after delivery is very stable.

Various samples for in-house verification

― Please provide a brief comment for users considering the UJV300DTF-75.

After all, I don't think you'll be able to see how awesome this machine is or how it performs until you actually use it once. Even though it is a new printing technology, the quality is very stable, I am not confused about the usability, and frankly I think it is a perfect score of 100. As an extreme example, even if a customer asks us to print on a soccer ball, it would be difficult to do so with a conventional flatbed machine or roll machine. However, if we have the UJV300DTF-75, we can try to meet the request, and that alone would be revolutionary. As for the initial cost, I don't see any reason not to recommend it, for example, it is only one month after the introduction and it is expected to be recovered within one year.

Also, as for the decisive factor for the introduction I mentioned at the beginning, Mimaki is supported by both sales and maintenance, so there is a strong sense of security. In particular, what I feel is definitely different from other manufacturers is that they provide various information on how to use the printer. From this point of view, it is hard to imagine that the potential of the UJV300DTF-75 will remain after its introduction.

The JFX600-2531 flatbed UV printer was introduced in March 2025. It is becoming an indispensable machine for the company, which has many short-delivery projects, such as productivity improvement of about three times compared with conventional machines and toggle print function which can continuously output without time loss. Recently, customers' needs have been focused on direct output because it can reduce the deviation of roll paper expansion and contraction and greatly shorten the delivery time.

User profile

- NameB&P Co.,Ltd.

- IndustryAs a company that provides "one stop support for sales promotion and marketing from both real and digital perspectives," we are developing various services, including inkjet printing services.

- AddressEdobori Fukoku Seimei Building 3F, 2-6-33 Edobori, Nishi-ku, Osaka-shi, Osaka, Japan

- Phone number+81-6-6448-1801

- URLhttps://www.bandp.co.jp/