A case study of Bikou Y.K., which has installed the JV330-130, was published in the sign and display industry magazine "POPEYE" , No. 266 (August 2023 issue).

The following is the published article in its original form.

The ease of use and output speed of RIP software are unparalleled by any other company

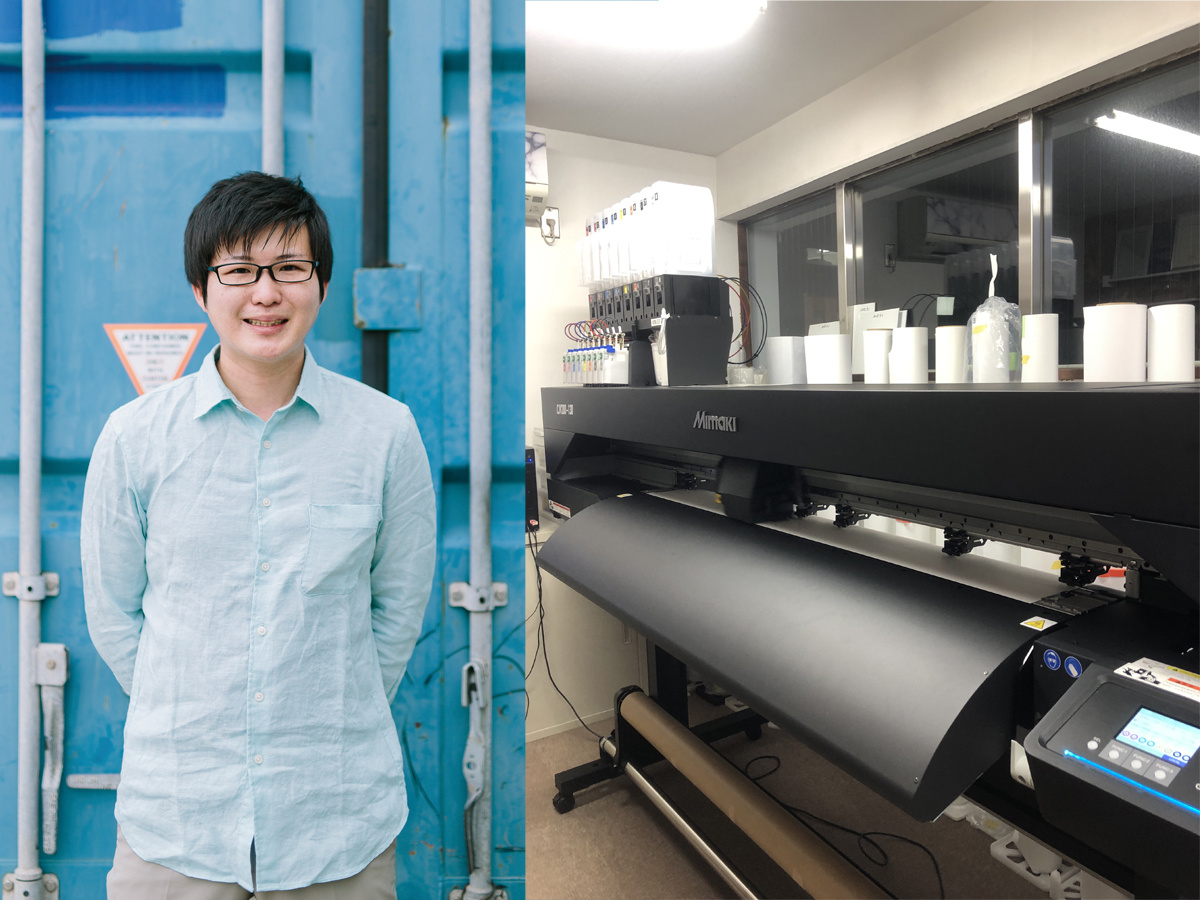

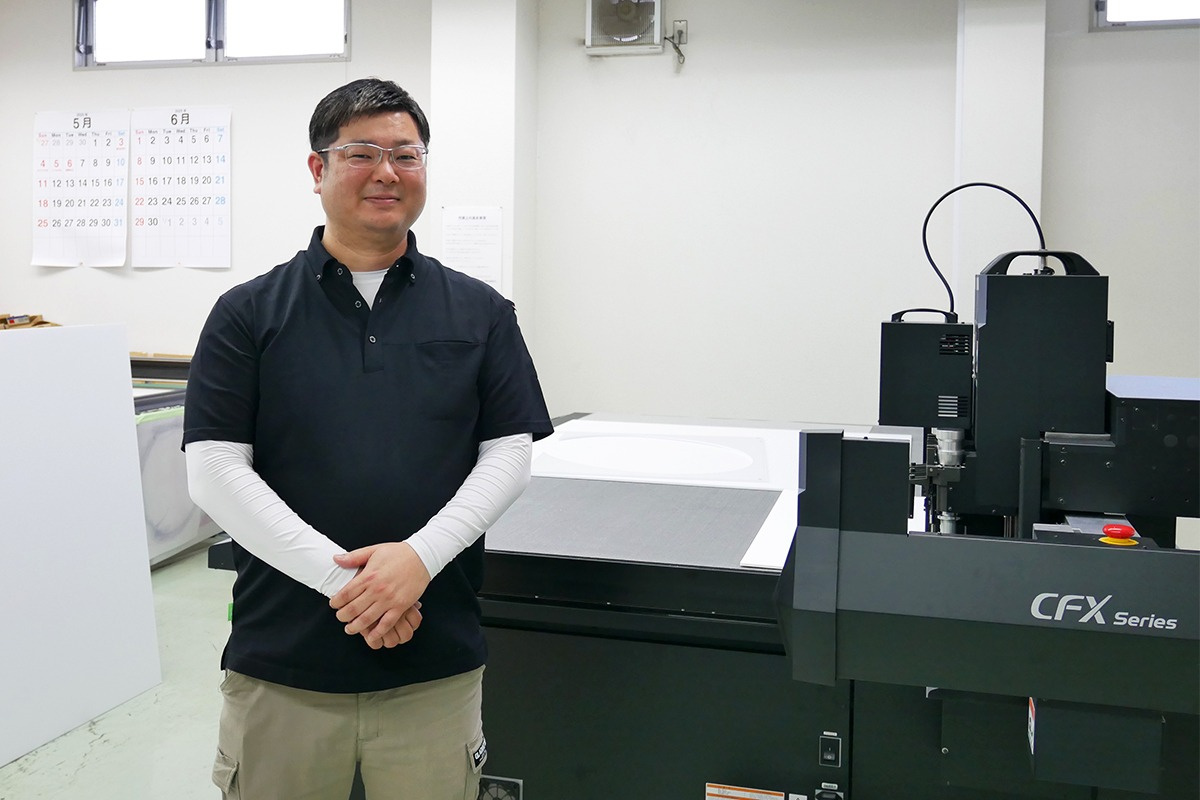

General Manager Mr. Kitayama

― Tell us about your company.

Our company mainly outputs short-term graphics for museums, exhibitions, and events. We also undertake related cutting work.

Currently, the president, Mr. Oguma, and I are the only two people in the company. Each of us has our own output machine, and we divide our work between the president, who handles graphics for museums and art galleries, and me, who handles exhibitions, events, in-store POP, and signage.

I have been involved in inkjet output for more than 20 years, since the days of water-based pigments, and the three printers I use now are Mimaki's JV300 eco-sol printer, the UCJV300 with UV ink, and the JV330-130, the latest model introduced about a year ago.

Mr. Kitayama watching over the output

― They are all Mimaki products.

I have used printers from many different manufacturers. Whenever I replace or add a new printer, I look at the latest models available at the time and consider them, but I often find that I have settled on a Mimaki product (lol).

There are many reasons for this, but first of all, I am used to using Mimaki products. Mimaki's RIP "RasterLink" is easy to customize by myself. You can specify details, and you can freely adjust every detail.

The other thing is support. Inkjet printers have a high production utilization rate, and we occasionally have cases that call for service. Mimaki's response is by far the fastest anyway. This has been consistent for a long time, and it makes a difference in our sense of relief.

― How did you come to install JV330?

The water-based pigment printer we were using at the time was not doing well, and its maintenance had expired, so we thought it was time to replace it. I heard that the "330" series would be released around that time, and I was curious to see what it would be like.

I considered other printers with good reputations, but when I saw the "JV330" in action, I knew I had to go with this one (lol).

― It's been a year since the operation.

Finally, I realize that we have recently settled down in many respects. As is the case with printers from any manufacturer, the latest models sometimes have unexpected problems at the start of operation. I had to contact support each time, but the Mimaki sales representative told me that I could contact them directly. Thanks to him, I was able to get a quick response.

My first impression after using the machine was, "It's fast!" I have a "JV300" left as a spare unit, but I hardly ever use it (lol). Our work mainly involves output that can be viewed at close range, so in many cases we print at a slower speed than the manufacturer recommends. This was taking a lot of time, but the JV330 is much faster even at my settings, and my work efficiency has gone up dramatically.

The colors are also very vivid, probably because of the orange ink. However, I feel that printers of all manufacturers are placing too much emphasis on "vividness" these days. I am sure there are such requests, but what I am often told by customers is, "Make sure the output is the same as that of the monitor". In this respect, the "JV330" can meet that request because it can adjust every detail in the RIP.

In many cases, data is customized in detail on the RIP.

― How do you like the value-added features?

The "Media changer" is nice because it allows us to attach three different types of media, which is very useful since 50m rolls of PVC media are very heavy and our installation space is small, so being able to leave some attached is a big help in terms of media storage space.

― About future prospects for the business

I have been working in this sign industry for a long time, and there are many changes in every era. The evolution of output machines is one of them, and I often talk with the president about how to "keep up" with them first.

Changes in deliverables are also noticeable. For example, one of our main jobs, explanatory panels used in museums and large private exhibitions, are being replaced by video equipment. As a company, we have to consider various options, whether to acquire work in other fields or to respond to video.

I have high expectations for Mimaki Engineering. When I used to use water-based pigment printers, I had no idea that solvent ink would improve image quality to such an extent and expand its applications. What kind of evolved products will you propose to our industry in the future? I am sure there will be hardships, but I am looking forward to it.

User profile

- NameBikou Y.K.

- IndustryInkjet output installation, marking film production and installation, T-shirt printing...etc.

- Address7-6-1 Minami-Senju, Arakawa-ku, Tokyo, Japan

- Phone number+81-3-3801-7167

- URLhttps://companylimited-bikou.studio.site/