A case study of Kori Tokyo Store which has installed the TRAPIS, was released in the website of the fashion business industry “Senken Shinbun” .

The following is the published article in its original form.

The Future of Printing with Mimaki Engineering's TRAPIS

As consumer needs diversify, manufacturers are required to respond to a wide range of needs. Kori Tokyo Store (Tokyo, President Mutsuo Kori), which has been engaged in ink-jet printing in Tokyo for about 20 years, has developed new customers in accordance with the changing times.

At the end of 2024, the company introduced "TRAPIS," a printing pigment transfer system developed by Mimaki Engineering. Taking advantage of the ability to print on a wide range of materials such as nylon and synthetic leather with one system, they started using it from the production of bags.

We asked Mr. Kazushi Kori, who is in charge of business operations, about the history of the introduction of TRAPIS and the possibility of the project.

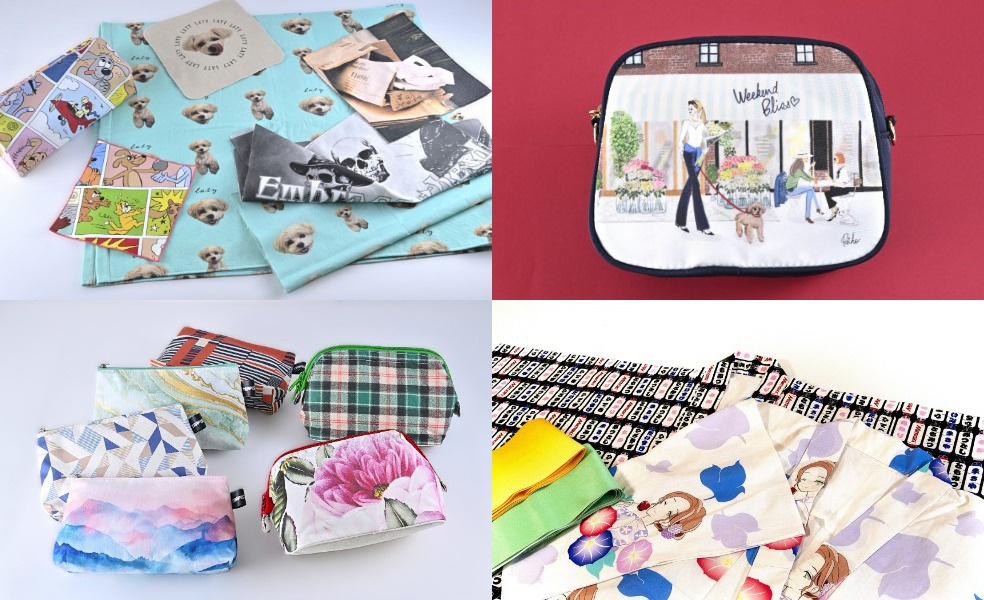

Pouch produced with TRAPIS

Kori Tokyo Store, which pioneered the introduction of inkjet printing in 1998.

Our company was founded in 1962 by our father (President Mutsuo Kori), who had experience in the textile business in Fukui Prefecture. He came to Tokyo and started selling lining materials for women. However, as sewing shifted from Japan to overseas, sales of lining fabric gradually decreased. In order to find a way to survive on the front side fabric, we introduced an inkjet printer in' 98. In overseas sewing, local procurement of fabric has advanced, but with high-quality front side fabric by on-demand printing, it will be possible to differentiate from fabric made overseas.

We adopted a dye ink type that prints directly on the fabric, and I think it was introduced in Tokyo ahead of other companies in the same industry at that time.

Kazushi Kori, Kori Tokyo Store

Shifted to sublimation transfer and succeeded in in-house production

In the case of dye prints, our facilities are limited, so we have to outsource pre-processing and post-processing such as steaming and washing. That's why we shifted our focus to sublimation transfer printing, which allows us to control production by ourselves as much as possible, 10 years ago.

I myself joined this company run by my father after I experienced working for an apparel maker. At a time when the DC brand was gaining momentum, our printers were used by many of these companies. However, design software like Illustrator and Photoshop was not as common as it is now, so it was hard to create data. Based on the paper design drawn by the designer, we took time to create the digital data.

"TRAPIS" is rich in color expression. Textile printing pigment ink is first printed on paper and then transferred to the fabric.

Utilized for bags under its own brand "Reiko Aoki"

It was the launch of our own brand that served as the basis for our TRAPIS introduction. "Reiko Aoki", which started in '05 and is characterized by New York style illustrations, has been producing goods such as bags and accessories mainly with sublimation transfer printers. Since its launch, it has gained a strong following and is sold through its own EC as well as pop-ups at department stores.

It was also significant that the company was able to develop sales channels for event goods while the movement for apparel stopped under the COVID-19. We have established contact with specialist traders, and are working on items such as towels for cheering goods and Japanese traditional outwear.

On the other hand, in sublimation transfer, the target material is limited to polyester, so we have been thinking for a long time that we would like to expand the range a little more. In the meantime, I heard that Mimaki, which we purchased sublimation transfer printers, has announced a new TRAPIS of printing pigment transfer.

TRAPIS is a method similar to sublimation transfer, in which printing pigment ink is first printed on a paper, which is then transferred on top of the fabric. Sublimation transfer can only transfer to polyester, but TRAPIS can transfer to all kinds of materials, which is a big advantage.

Transferring from transfer paper to fabric while controlling conditions to suit the fabric and material using a TRAPIS exclusive transfer machine.

Printable on all kinds of materials, expect to see a wider range of items

The own brand "Reiko Aoki" is mainly for bags, so in addition to polyester, if it can print on nylon, synthetic leather, and other materials that have not been handled before, I felt that there is a possibility that the range of items will expand. Because it is the same paper transfer, I felt that I could make use of the know-how of sublimation transfer so far, which was also the point of deciding to introduce it.

Conventional dye-based printing of nylon requires large-scale equipment, and there have been almost no systems for printing on synthetic leather. However, TRAPIS can be used for a wide range of materials because it uses pigment ink and simple paper transfer.

In December of 2024, we introduced a TRAPIS printer and an exclusive transfer machine, and we are planning and developing them. Specialized TRAPIS transfer machines apply the high pressures required to transfer pigments and control this depending on the type of material. It can also be used for sublimation transfer if the pressure is turned off. TRAPIS needs to determine the optimum transfer conditions for different materials, and is accumulating production know-how. On the other hand, the transfer speed can be achieved in a shorter time than sublimation transfer, and it is possible to cope with high production once you get used to it. Above all, competition in sublimation transfer is increasing, so we are planning to shift to a new system, TRAPIS, and take a step forward.

Print on various materials such as synthetic leather, cotton linen, cotton, nylon, etc. to expand the range of items

Proven track record of receiving high praise from leading brands for capabilities in handling composite materials

Since the introduction of TRAPIS, we have gradually accumulated know-how, and we have already been adopted by leading designer brands, and we are feeling a good response. In recent years, the use of composite materials such as mixed spinning and weaving has increased, and there are many cases that cannot be printed using conventional methods. TRAPIS can handle these materials, and this was highly appreciated by designer brands.

Established technology for transferring onto nylon and synthetic leather for commercialization

Under our own brand, Reiko Aoki, we plan to commercialize nylon with established technology and start selling it at the end of June. Next, I want to make something with synthetic leather. If this print goes well, I expect to be able to spread the item.

We also intend to use our own brand as an opportunity to win orders for business-to-business printing. I haven't tried it yet, but it can be made of wool. I would like to take advantage of TRAPIS's strengths in that the process is simple and it can handle all kinds of materials, and shape customer needs.

In the midst of accumulating know-how for a wide range of materials.

User profile

- NameKori Tokyo Store

- IndustryApparel OEMs

- Address1-5-7 Misuji, Taitou-ku, Tokyo, Japan

- Phone number+81-3-3862-0838

- URLhttp://www.kori.co.jp/