Improve the efficiency and accuracy of cutting operations and develop new customers. CFX's Cost-Performance and Scalability, Backed by a Handful of Quality-First Company.

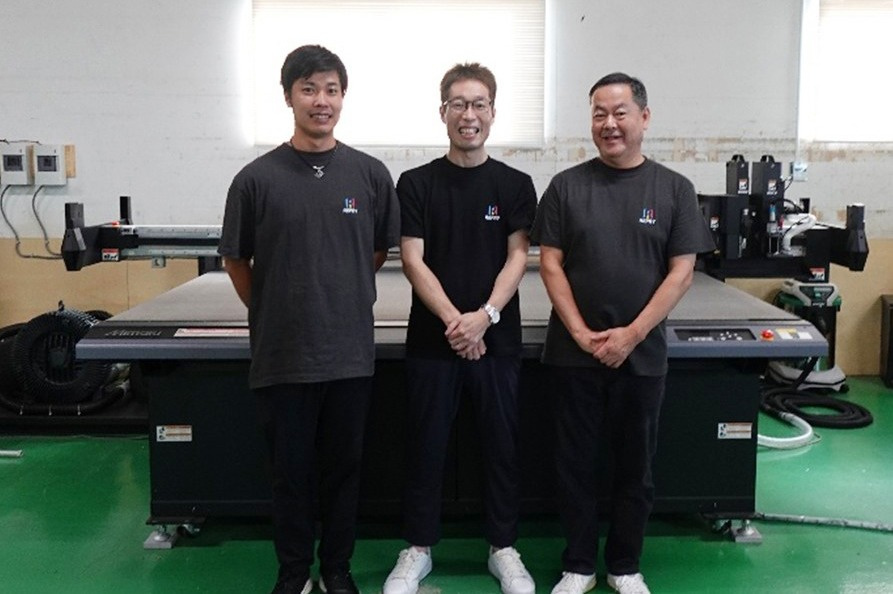

Print House Kaneko Co., Ltd., which specializes in the decoration of events and exhibitions, has been publishing its monthly production records on its website for five years without fail. The volume of orders received has been increasing steadily, and the company now produces four times as much work as it did at the beginning. Despite this, the company has remained a small, elite group with only five employees, and it is surprising to learn that the company is constantly improving the quality of its products, which is one of its strong points.

As we face the 2025 problem of a hyper-aged society, a rapid increase in workload could be a happy scream. This report will examine the company's efforts to save labor and increase production efficiency.

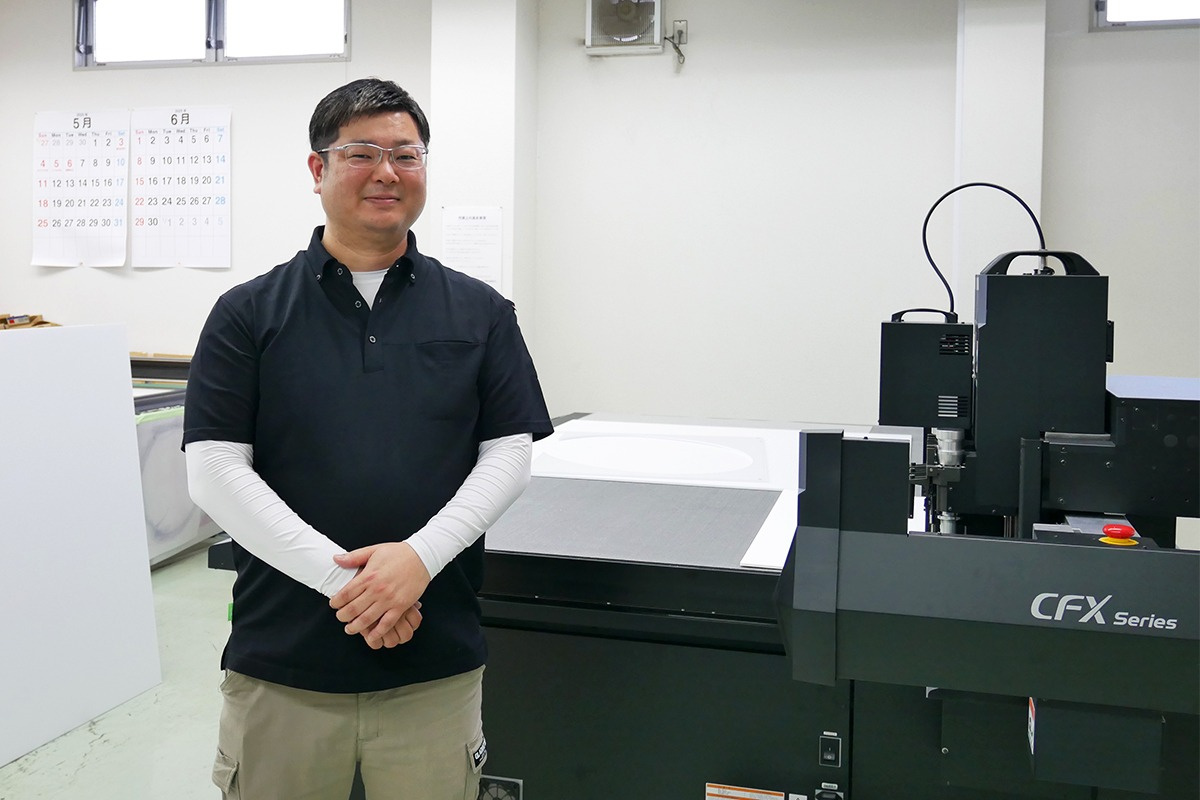

Representative Director Reiji Kaneko

— First of all, please tell us the history of your company's foundation.

Based on nearly 15 years of experience in inkjet printing and processing at a major output vendor and a signature production company, I founded my company in my own home in 2011. I was immediately entrusted with the display and decoration of a block toy and POP parts manufacturer, and I was unexpectedly praised by clients for the excellent finish. I still vividly remember that I felt a great sense of achievement.

I am grateful that it was thanks to the printing quality of the solvent machine "JV33" of Mimaki, which I purchased for the first time at that time, and I think it is not an exaggeration to say that we have progressed together with the machine.

— How have things changed since then?

Fortunately, we became a corporation in Shinjuku, Tokyo, in 2012, the year after we were founded. Our business expanded with the introduction of customers, and until the COVID-19 disaster, we had been growing steadily without any sales activities. However, during the COVID-19 disaster, the work related to events and exhibitions completely stopped, and I really had a headache. However, I am proud to say that no matter how hard times have been for me, I have always maintained that I would never sell at a discount.

Our customers have evaluated our quality, and that has expanded the circle of our work. So, for me, quality is an indispensable and unique strength.

— I am surprised that you have not engaged in any sales activities for nearly 10 years since you established your company. How do you increase customer satisfaction?

I do not mean to brag, but I have been using printers every day since the early days of digital printing, when color adjustment is not as easy as it is today, so I am confident in my know-how in inkjet printing. In addition, even in the case of events and exhibitions, small differences at first glance can have a significant impact on quality. For example, lamination is always applied, and cutting work is mechanized to improve accuracy.

For short-term indoor displays such as exhibitions, you may think that lamination is unnecessary, but from the point of view of the site, it can easily become a cause of construction defects. It is obvious that there is a difference in accuracy between manual cutting and machine cutting.

We introduced cutting plotters from the very beginning of our business. In the following year, we installed the "CF2-1218" flat-bed type. For example, imagine the time and effort required to cut a circle with a human hand. With a machine, as long as you set it up properly, it only takes a moment.

If you compare the cost of the machine with the cost of labor, it is a difference that is so great that you don't even need to play with a calculator.

CF2-1218 to save manpower in cutting operations since 2013

— I see, so now the difference in post-processing naturally affects the quality.

Supported by the image quality and high productivity of the Mimaki's printer since the time of JV33, the post-processing by the cutting plotter CG-130FXII Plus and CF2 has further improved the quality of the product.

When the factory was moved to Itabashi, Tokyo in 2024 due to its limited capacity, the new flatbed cutting plotter "CFX-2513" was introduced. It is equipped with tools for half, sheet, panel cut and V-cut, and can perform post-processing of large sizes such as life-size panels in one stop. It plays a role in improving the efficiency of the production line.

In 2024, CFX-2513 was newly introduced in order to further improve responsiveness and efficiency, and in May 2025, it was expanded to CFX-2531.

— What is the background of the introduction of CF2 and CFX, and how are they running?

The reason why we introduced CF2 about 12 years ago was because the basic usability was the best when we examined machines from multiple companies at that time. Also, as you will know once you use it, all models have a certain level of stability in quality. After all, that is a very big factor in machine selection.

The CFX takes advantage of a processing speed of up to 100cm/sec, and has been introduced with the aim of improving productivity and enhancing adaptability. Again, there are almost no cases where defects are found when actually using Mimaki's machine. The CFX also works as expected and is even more highly efficient. The good thing is that it comes with "FineCut," a software that can cut directly from Adobe Illustrator, as a standard. Not only me but also part-time employees who don't know much about machines can work smoothly. This is one of the decisive advantages that other companies' machines do not have. The operation feeling of the main body is the same between CF2 and CFX, so it is also helpful that you can work stress-free.

As for the operation status, both machines are working almost at full capacity. The CF2 mainly cuts panels and posters, and the CFX also performs processing utilizing the V-cut and folding functions. The processing accuracy of the V-cut is also excellent, and small POP (photo below) folded with styrene can be made beautifully. It has already been adopted by several companies. Since the CFX has been introduced, it has become possible to make fixtures, so I would like to continue making various things in the future.

![Three-dimensional POP [BOX Panel] (Material: styrene board)](https://d2w577gk9zpoty.cloudfront.net/archives/143/202506/d2443d171b6e5affd31327b6a4c4dabfdadcc33b4f661d6b4e0998b57060ab57.jpg)

Three-dimensional POP [BOX Panel] (Material: styrene board)

Before the introduction of CF2, we had a two-person team for manual cutting, which was limited to about 100 cuts per day; after the introduction of CF2, the number of sheets we could cut did not change significantly, but we were able to handle 100 cuts with one person, so labor costs were reduced.

Furthermore, with the introduction of CFX, we are now able to cut more than 300 sheets per day, which enables us to accelerate our work significantly. We were able to increase the number of orders per month, but at the same time, overtime hours, which used to be two to three hours a day before, have been reduced to zero, and profits have also increased, all of which are good things about the introduction of CFX.

Immediately after the introduction of CFX, we received a job to cut about 200 A2 panels, and we expected to spend two days on the job, but we were very surprised to find that it was done in four hours.

— Specifically, how do you feel about CFX?

If you ask me how satisfied I am with my work, I can honestly say that I am 100% satisfied. The staff are also happy that their overtime has decreased considerably.

In mid-May, we plan to expand the table size from CFX-2513 to CFX-2531 (3,190 x 2,540 mm). 2531 can set the next 4 x 8 board in the opposite area while processing, enabling continuous cutting without time loss (by the toggle function). We hope that this will further contribute to improved production efficiency.

The larger the size of the cut sheet, the less efficient it is if it is done by hand. In this respect, the ability to automate the cutting of approximately 3.1m in size will simply lead to greater efficiency. In addition, since most exhibition booths are 2.7 m high, we will be able to produce single sheets for them as well, and we hope to proactively acquire jobs that we could not get before. Although it has only been five months since we introduced CFX, we were able to use the increased profits to increase our sales force and further increase the number of orders, and we are hopeful that CFX-2531 with its table expansion will further increase efficiency and increase the number of orders.

*Expanded to CFX-2531 in May 2025

In addition, since express work can be contracted for at a higher unit price than usual, we want to differentiate ourselves from other companies and provide high-quality services by actively accepting orders for urgent work using high-efficiency CFX. We can provide high-quality products quickly, rather than quickly or badly, so we have confidence in that point.

— What are your frank opinions on after-sales service?

It's been the same since JV33, and if something happens, they will come right away, so I'm surprised. They are very diligent. In addition, considering that it's made in Japan, we have introduced CFX. If it takes time to replace parts, there is no point in enhancing productivity and efficiency.

— Finally, do you have any comments for those who are considering implementing CFX?

In this price range, in view of this performance, the cost performance is superb. After using it, there are no dissatisfied elements, and if anyone is hesitant about introducing CFX, I will recommend it with my seal of approval.

User profile

- NamePrint House Kaneko Co., Ltd.

- IndustryPrinting and Processing

- AddressFactory/Office: Urata Building 1F, 48-7 Oyama Kanai-cho, Itabashi-ku, Tokyo, Japan

- Phone number+81-3-6905-9183

- URLhttps://phkaneko.jp/