Entry Model Sublimation Transfer Inkjet Printer for Textile Application

- Expanding the 100 Series lineup -

>>Expert printing made easy. <<

TS100-1600 | Product information

Nagano, Japan, January 20 2021

Mimaki Engineering Co., Ltd. (Headquartered in Nagano Prefecture, Tomi City; President, Kazuaki IKEDA) engaged in industrial inkjet printers, cutting plotters, and 3D printers announces the release of the "TS100-1600" sublimation transfer inkjet printer for textile and apparel applications, to be available worldwide starting February 2021.

In recent years, in the textile and apparel market, with the diversification of customer needs, the demand for on-demand printing, which can reduce inventory by producing small lots and various kinds of products in a short delivery time, has increased instead of inventory sales of mass-produced products.

Digital printing is getting more market attention as an efficient production method that can reduce inventory because it does not require a plate-making process and can produce small lots and a wide variety of products on a case-by-case basis to be possible to shorten the time from planning to product arrival at the store. On the other hand, those exist who are hesitant to go digital because of the initial installation costs, including the purchase of printers. The TS100-1600 meets the market needs of the textile and apparel industry, and as an entry-level model with high performance and an affordable price, it can be used with confidence by a wide range of customers who are considering the introduction of digital printing.

The TS100-1600 is a sublimation transfer inkjet printer newly added to the entry-level “100 Series” lineup, which offers an excellent balance of operation performance, image quality, speed, and cost.

The print width of 1,600 mm, which is frequently used in the textile/apparel industry, is supported. Even though the printer is a reasonable entry-level model, it achieves high productivity with a print speed of 70 m²/h in the fastest mode, which is about twice as fast as our conventional model for textiles *1. In addition, the use of a one-liter bottle ink for the first time in our sublimation transfer models helps cut the running cost in about half compared to our conventional model *1 (when equipped with standard 440 cc cartridges), and enables stable, long-term operation due to the reduced frequency of ink replacement.

The printer is also equipped with a variety of features, including NCU (Nozzle Check Unit)*2, NRS (Nozzle Recovery System)*3, and MAPS4 (Mimaki Advanced Pass System 4)*4 to ensure stable, high-quality prints. Moreover, the DAS (Dot Adjustment System) function is adopted to automate dot position correction and feeding amount correction that were previously done manually, reducing the workload on the operator drastically.

The TS100-1600 is compatible with Mimaki’s two types of original RIP software, TxLink4 Lite and RasterLink7 to ensure beautiful prints and ease of use. You may choose either one as a standard provision when purchasing the product.

Mimaki Engineering Co., Ltd. upholds the management vision of "novelty and difference" and will continue to strive to be an innovator company that provides customer-oriented products.

*1 When compared to our previous models: JV150-160 (equipped with water-based sublimation ink) and TS30-1300

*2 NCU: A function that automatically detects the status of nozzles using the sensor, and performs auto cleaning when a missing nozzle is found

*3 NRS: A function that automatically replaces defective nozzles with other nozzles if there is a problem left unsolved by the nozzle cleaning, and ensures uninterrupted printing with stable image quality

*4 MAPS4: A function that prints pass boundaries fading in gradation to reduce banding (horizontal stripes), uneven color, and glossy streak

Overview

- All-in-one entry model that can handle everything from sample creation to large-lot production

- High speed printing of up to 70 m²/h for high productivity

- Printer with improved operability using the comprehensive technology of Mimaki

- Compatible with Mimaki’s two types of original RIP software to ensure beautiful prints and ease of use

Features

1. All-in-one model that can handle everything from sample creation to large-lot production

Thanks to digital printing that does not require plate-making, orders can be placed for as little as one sheet, making it possible to reduce costs for small-lot production.

2. High speed printing of up to 70 m²/h for high productivity

Various print modes are available to meet your work needs, from the fastest mode (70 m²/h) to practical quality mode (46 m²/h) and high quality mode (19 m²/h). Also, in the fastest mode, productivity is about twice as high as that of our conventional model (JV150-160).

3. Latest features that achieve Mimaki quality

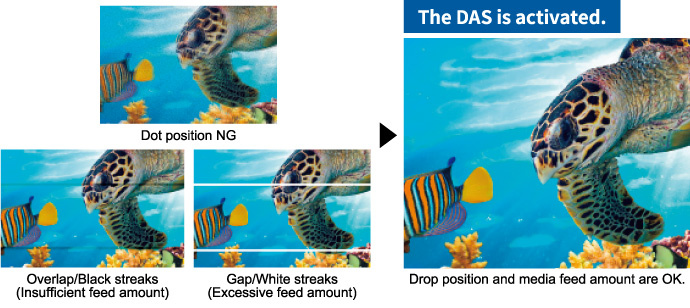

Dot position / Feed auto correction function “DAS”

Automated visual drawing adjustment (dot position correction and feeding correction) manually implemented in previous models. By saving operators time and effort needed for such adjustment, variation in adjustment is prevented.

Mimaki technology enabling stable high-quality printing

MAPS4

Since pass boundaries generally become straight, slight misalignment results in banding or uneven color. The “MAPS4 (Mimaki Advanced Pass System 4)” functionality provides gradation to printed pass boundaries and reduces banding and uneven color, achieving a beautiful printing result.

With MAPS

Because printing pass boundaries are faded in gradation, a beautiful image quality is ensured by reducing banding and uneven color.

Without MAPS

Banding occurs at pass boundaries. Image quality is damaged seriously because horizontal streaks and uneven color printing are brought about.

NCU & NRS automatically detects missing nozzles and performs recovery

NCU (Nozzle Check Unit) automatically detects nozzle condition. When the NCU detects a missing nozzle, it automatically performs cleaning. In case problem is not solved by cleaning, NRS (Nozzle Recovery System) automatically replaces defective nozzles with alternate nozzles, enabling users to resume operation without waiting for repairing.

4. Two software choices: “TxLink4 Lite” and “RasterLink7”

You may choose either one as a standard provision when purchasing the product.

- “Parallel RIP function”, “Load balancing function”, and “Variable print function” of the TxLink4 are supported to increase productivity.

- “Multicolor profile creation function” allows you to create your own profile for more vivid and beautiful results. The profile can be created automatically by only following the instructions of the wizard to print and measure the color chart *5.

*5 Please use a color measuring tool (which should be prepared separately) after color development.

- RasterLink7 is a RIP software that has realized both ease of use and advanced capabilities. With improved RIP processing speed, usability, and productivity, it supports variable printing.

Specifications

| Item | TS100-1600 | |

|---|---|---|

| Print head | On-demand piezo head (2 staggered layout) | |

| Print resolution | 360 dpi, 600 dpi, 720 dpi, 900 dpi | |

| Ink | Type/ Color | Sb610 (Bl,M,Y,K) |

| Capacity | 1L bottle | |

| Print gap | Dual manual adjustment (2/2.5mm) | |

| Maximum print width | 1,610 mm (63.4") | |

| Media | Maximum width | 1,620 mm (63.8") |

| Thickness | 1 mm or lower | |

| Roll diameter | φ250 mm or less | |

| Roll weight | 45 kg or less | |

| Roll inside diameter | 2 inch / 3 inch | |

| Media cutting | Automatic cutting using the head section cutter | |

| Winding/Feeding | Winding (automatic winding)/Feeding (holder) | |

| Interface | USB2.0, Ethernet 1000BASE-T | |

| Power supply | Single-phase AC100-120 / 200-240V±10%, 50/60Hz±1Hz | |

| Certifications | VCCI class A, FCC class A, CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, ENERGY STAR®, RCM, EAC | |

| Dimensions (W×D×H) | 2,775 x 700 x 1,475 mm (109.3 x 27.6 x 58.1") | |

| Weight | 166 kg (366 lb) | |

*6 Specifications, designs, dimensions, and other information stated in this list may be subject to change without notice due to technical improvement etc.

About Mimaki Engineering

Mimaki Engineering develops, manufactures, sells, and maintains industrial inkjet printers, cutting plotters, 3D printers, their inks, and software. We aim to be an innovator that constantly delivers "newness and difference" to our customers by providing total solutions for the printing process for the sign graphics, industrial products, and textile apparel markets.

Company/IR site: https://ir-eng.mimaki.com/

Product site: https://mimaki.com/

Contact

MIMAKI ENGINEERING CO., LTD.

Global Marketing Department

1628-1 Shigeno-Otsu, Tomi-city, Nagano 389-0512 JAPAN

Tel: +81-(0)268-80-0078 / Fax: +81-(0)268-80-0041

Web Inquiry form

TS100-1600 | Product information