A cloud software service enabling automatic error correction and optimization of 3D forms for the data used in 3D printers

Nagano, Japan, October 5, 2021

Mimaki Engineering Co., Ltd. (Head office: Tomi-shi, Nagano-ken, CEO: Kazuaki Ikeda), specializing in industrial inkjet printers, cutting plotters and 3D printers, announced the release of a cloud software service, the “Mimaki 3D Print prep Pro (3DP³)”. The software enables automatic correction of errors, optimizing the 3D form data used in 3D printer operating*1 The software is the first subscription-based service to be provided from Mimaki Engineering, scheduled for launch on October 5, 2021.

COVID-19 epidemic triggered a renewed appreciation for 3D printers. 3D printers were actively used to create face shields amidst the disruption of supply chain and the shortage of protective gear became an imminent issue in the medical field. Based on the calculations of droplet infection simulation by the supercomputer “Fugaku”, design information of face shields intended for use to during meals was shared on various websites as open data. The data allowed anyone with a 3D printer and the necessary materials to produce face shields. With Corona, we believe that the use of 3D printers will expand from industrial fields to personal use.

While 3D printers are becoming more and more accessible, it is necessary to check the 3D data for errors in advance when printing from 3D data. Software with various capabilities for error correction is still expensive and requires knowledge and time to learn to handle the 3D data. The requirement for 3D data correction has been a challenge obstructing the further spread of 3D printers.

The new “Mimaki 3D Print prep Pro” allows for the necessary correction of errors automatically with a simple operation when printing from 3D data, and furthermore, the software can optimize the shape to be suitable for 3D models. This makes it easy for users unaccustomed with the handling of 3D data to correct errors, thereby contributing to the reduction of the time required for data correction. The product incorporates eight primary functions: “thickness correction,” “gap-filling correction,” “hollow shape correction,” “clear part cut correction,” “texture data optimization,” “material color activation setting,” “hole-filling correction,” and “VRM data correction.” When making detailed corrections, it is also capable of arbitrarily specifying numerical values, providing for further automatic modifications. By checking for and correcting the error information prior to printing, reliable printing without wasting time and materials is ensured. The software is compatible with 3DUJ series*2 of Mimaki UV curable inkjet full color 3D printers, enabling full color 3D printing in over 10 million colors.

“Mimaki 3D Print prep Pro” is the first-ever subscription-based cloud software service from Mimaki Engineering, which allows users to use the software for a monthly fee of $50*3. For more information and subscriptions to use the “Mimaki 3D Print prep Pro”, please visit the Mimaki product website: https://mimaki.com/product/software/3d/3dp3/.

Mimaki Engineering Co., Ltd. upholds the management vision of “something new, something different” and will continue to strive to be an innovator company that provides added value to its customers.

*1 3DP³ may not be able to provide the required correction results depending on the content and shape of the error. In this situation, manual or automatic correction using another 3D data correction software may be required.

*2 3DUJ-553 and 3DUJ-2207

*3 The amount of monthly payment may vary in accordance with the exchange rate with the US dollar depending on the currency settings for credit cards used by the customer.

Overview

- Cloud software services of 3D data auto-correction compatible with 3DUJ series enabling full-color printing (over 10 million colors).

- Mimaki Engineering's first $50/month subscription system allowing for easy and convenient 3D data correction work

Features

1. Automatic correction of 3D data errors

Depending on the method of data creation, the data may not be suitable for 3D printing. The product is a software featuring automatic error correction of 3D data, optimizing the model configuration as required.

<Workflow of 3D printing>

2. Ease of Use

Simplistic browser-operated workflow. Simply specify the correction method to complete the correction after data upload. An automatic notification email will be sent when correction is complete.

3. Appropriate correction method can be selected from among four available options.

Software allows for quick specification of conditions for automatic correction depending on the type of 3D models by selecting from among “three simplistic correction types”: “Character” suitable for character models, “Mechanical” suitable for mechanical models, and “Vehicle” suitable for automobile-like models. In addition, the “Pro” option offers an alternate method of data correction. The conditions for automatic correction can be specified according to the intended application.

4. Eight functions

THICKNESS (thickness correction)

This function increases the thickness of the thin part of the 3D data. By increasing the thickness, the strength of the object is increased. This function is also effective for 3DUJ series when the color is transparent due to the thin thickness.

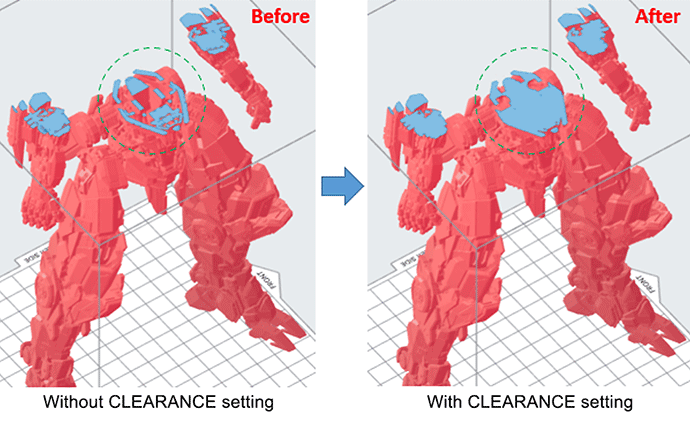

CLEARANCE (gap-filling correction)

This function fills in the internal gaps of the 3D data. By filling in the internal gaps, you can increase the strength of the printed object.

HOLLOWING (hollow shape correction)

This is a function to make the shape of 3D data hollow and useful for reducing the weight of a printed object.

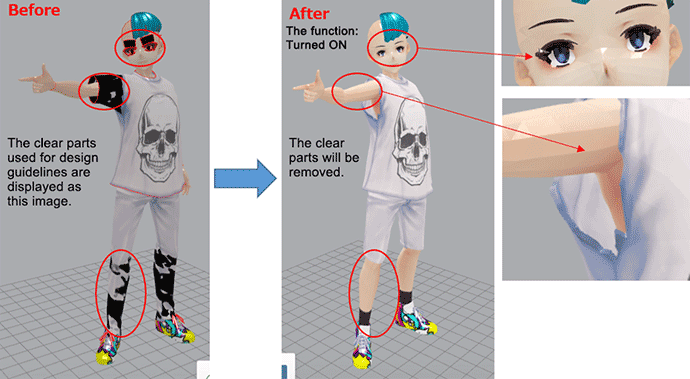

CUT TRANSPARENT PARTS (clear part*4 cut correction)

3D data such as 3D games and videos that are not created for 3D printing may contain clear parts that are unnecessary for 3D printing. This function removes these clear parts.

*4 Part to be used as guidelines in the process of creating 3D data

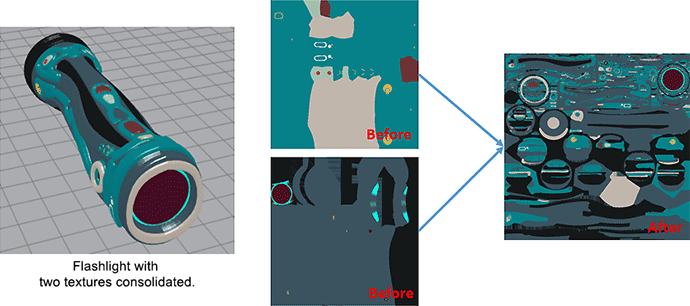

TEXTURE OPTIMIZATION (texture data optimization)

Automatically optimizes the placement of texture data. Multiple texture data can be consolidated into a single data, which improves the processing speed during 3D printing.

MIX TEXTURE AND MATERIAL COLORS (material color*5 activation setting)

This function reflects the material color and texture in the 3D data to the 3D printing data. This function is effective when the design of the object is specified in terms of both material color and texture.

*5 The color of the material itself.

CLOSE HOLES (hole-filling correction)

This function fills in the holes in the 3D data by automatically adding color and filling in the holes with reference to the texture information around the 3D data.

USE VRM PIPELINE (VRM data*6 correction)

This function specializes in modifying "VRM data" created for avatars. It performs multiple modifications such as removing clear parts used as guidelines in the creation process and smoothing the surface.

*6 Dedicated file format for avatars used in VR applications

5. Easy-to-understand confirmation screen

The number of errors, model information, shape and color of the 3D data can be confirmed before and after correction, also allowing for the confirmation of correction result by showing cross-section of the 3D data with the slice-view function.

Specifications

| Website URL | https://mimaki.com/product/software/3d/3dp3/ |

|---|---|

| Recommended browsers | Mozilla Firefox, Google Chrome |

| Subscription fee | $50/month |

| 3DP³ Cloud Server | SSL Server |

| Recommended Computer specifications | Depends on the operating specifications of the browser software*7 |

| Required PC HDD Capacity | Depends on the customer 3D data storage capacity |

| Number of data uploads | Unlimited |

| Data upload size limit | 1,000MB per data |

| Number of 3D data that can be uploaded at one time | 1 piece |

| Input data format | stl, obj, 3mf, dae, vrm |

| Output data format | stl, obj |

| Supported language | English |

*7 3DP³ is available for use on PCs with specifications meeting the standard operational requirements of the browser software.

About Mimaki Engineering Co., Ltd.

Mimaki Engineering develops, manufactures, sales, and maintains industrial inkjet printers, cutting plotters, 3D printers, inks, and software. By providing total solutions for the printing process for the sign graphics, industrial products, and textile apparel markets, we aim to be an innovator that constantly delivers "newness and difference" to our customers.

Company/IR website: https://ir-eng.mimaki.com/

Product website: https://mimaki.com/

Contact

MIMAKI ENGINEERING CO., LTD.

Global Marketing Department

1628-1 Shigeno-Otsu, Tomi-city, Nagano 389-0512 JAPAN

Tel: +81-(0)268-80-0078 / Fax: +81-(0)268-80-0041