Nagano, Japan, September 17th, 2025

Mimaki Engineering Co., Ltd. (Head office: Tomi-shi, Nagano, Pref.; President: Kazuaki Ikeda), is to announce its release of the sublimation transfer inkjet printer "TS200-1600 (hereinafter TS200)" and will be exhibited for the first time in the world at The Print Show (Birmingham, UK) to be held from September 23, 2025.

TS200-1600 | Product information

1. Current State and Challenges of the Sublimation Transfer Printing Market

Sublimation transfer printing is a printing method that can produce vivid, full color designs on polyester fabrics and polyester coated materials. It involves printing with specialized ink onto sublimation transfer paper and then using heat to infuse the ink into the material—a simple process that is widely used in various application such as fashion apparel, sportswear, and custom goods. (Figure 1)

In recent years, against the backdrop of the expansion of on-demand production and e-commerce sales, an environment has been established that facilitates the easy sale of small-volume, multi-item products. Consequently, the adoption of sublimation transfer printers by small-scale business operators has increasing. At the same time, there is a shortage of skilled printer operators at production sites, and the increased workload of rework due to inconsistent quality. For this reason, there is a need for printers that can be easily handled by anyone and provide stable, high-quality printing.

Fig1. Major works of sublimation transfer printing

2. The Expanding Possibilities of the TS200's Expressive Power

The newly announced TS200 makes high-quality printing easy even for those who are new to sublimation transfer printers. A single high-density, high-resolution print head "330 Engine" which is used in our flagship printers is adopted in TS200 and can express uniform, beautiful high-concentration colors and intricate designs.

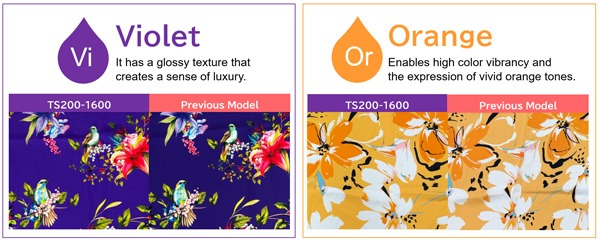

In addition to the standard Four-colors of ink, new colors of violet and orange are available. Reproduce sophisticated blue-purple tones and vibrant, dynamic orange gradations to enhance the clarity of fashion apparel and uniform designs.

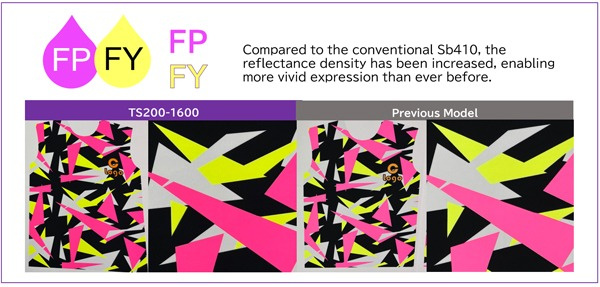

Additionally, FP and FY with significantly higher concentrations than conventional options, are also available, making them ideal for creating sportswear and flags with high branding impact.

The TS200 is a new standard model for entry users that can be used for a wide range of applications from apparel, goods and fabric signs in one unit.

3. Upcoming Schedule

The TS200 is scheduled to go on sale in October 2025 and expected to sell approx. 1000 units per year. (worldwide)

We plan to exhibit at trade shows in various countries, starting with the following exhibition.

Mimaki Engineering Co., Ltd. with its management vision of "Something New, Something Different," will continue to pursue new technological innovations to achieve the "beauty and speed" that our customers demand.

Features of the TS200

① Achieving high image quality and high quality, greatly expanding the scope of sublimation transfer printing work

Equipped with a high-density, high-resolution print head and our proprietary high-quality imaging technology, it delivers beautiful, uniform high-density solids and intricate designs.

Additionally, the newly added violet and orange inks enable vivid printing of previously dull bluish purples and bright oranges prone to looking dull. This significantly expands the range of color expression, meeting diverse design needs from fashion and uniforms to interior design.

Furthermore, we have added fluorescent pink and fluorescent yellow inks with higher concentrations than conventional products to our lineup, making them ideal for creating sportswear and fabric signs with high branding impact.

Figure 2. Color Tone Comparison at Violet and Orange Output

Figure 3. Color Tone Comparison at FP and FY Output

② Features that are easy for anyone to use and enhance operational efficiency

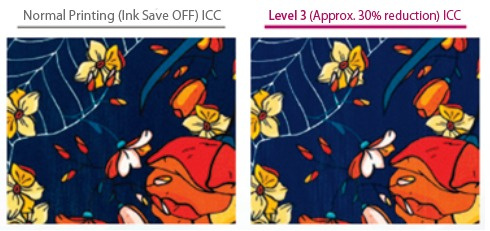

Equipped with the Dot Adjustment System 1 (DAS1), it delivers stable, high-quality results even for first-time users of sublimation transfer printers (Figure 4). Additionally, it supports the "Ink Save feature," which reduces ink consumption while maintaining color balance with just two clicks, even without specialized color adjustment knowledge (Figure 5).

Furthermore, it supports the dedicated MRA (Mimaki Remote Access) app for operating printers remotely, as well as the cloud-based monitoring tool "PICT," which visualizes operational status and ink usage to assist with production planning. This provides powerful support for enhancing customer operational efficiency and productivity.

For more information on MRA, please see here.

For more information on PICT, please see here.

Figure 4. Image Quality Comparison Before and After Automatic Adjustment Using DAS

Figure 5. Color Comparison Using the Ink Save Function

③ Equipped with support functions to prevent workflow interruptions

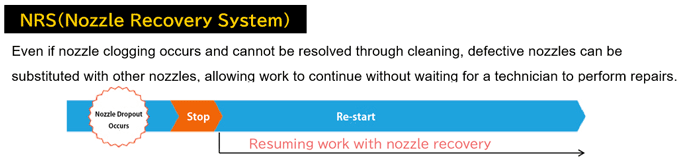

Even if a nozzle malfunctions in the print head*, the Nozzle Recovery System (NRS) allows you to register the faulty nozzle and continue printing (Figure 6). This enables you to proceed with work without waiting for a service engineer, minimizing downtime and ensuring stable production.

*The support function may not operate depending on print conditions or nozzle clogging status.

Figure 6. NRS Workflow Diagram

Main Specifications

| Items | TS200-1600 | |

|---|---|---|

| Print head | On-demand piezo head | |

| Print resolution | Y:300, 600, 900 dpi X:600 dpi | |

| Ink | Type/Color | Sublimation Dye Ink: Sb411 (BL,M,Y,K,Vi,Or,FP,FY) |

| Capacity | 2L Ink Pack | |

| Max. Print Width | 1,610 mm (63.4") | |

| Media | Max. Width | 1,620 mm (63.8") |

| Roll weight | 25 kg (55.1 lb) or less [45 kg (99.2 lb) or less with option *1] | |

| Interface | Ethernet 1000BASE- T(Recommended)、USB2.0 Hi-speed | |

| Power supply | Single-phase AC100-120 / 200-240V±10%, 50/60Hz±1Hz x1 | |

| Power consumption | Max. 250W or less | |

| Certifications | VCCI class A, FCC class A, ETL IEC 62368-1, CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, Energy Star, RCM, KC, UKCA |

|

| Dimensions (W×D×H) | 2,770 x 748 x 1,623 mm (109.1 x 29.4 x 63.9") | |

| Weight | 155 kg (341.7 lb) | |

*1 OPT-J0502 level foot OPT can handle up to 45 kg of media.

*Specifications, designs, dimensions, and other information stated in this list may be subject to change without notice due to technical improvement etc.

About Mimaki Engineering Co., Ltd.

Mimaki Engineering develops, manufactures, sales, and maintains industrial inkjet printers, cutting plotters, 3D printers, inks, and software. By providing total solutions for the printing process for the sign graphics, industrial products, and textile apparel markets, we aim to be an innovator that constantly delivers "Something New, Something Different" to our customers.

Company/IR website: https://ir-eng.mimaki.com/

Product website: https://mimaki.com/

Contact

MIMAKI ENGINEERING CO., LTD.

Global Marketing Department

1628-1 Shigeno-Otsu, Tomi-city, Nagano 389-0512 JAPAN

Tel: +81-(0)268-80-0078 / Fax: +81-(0)268-80-0041