High Performance Flatbed UV Inkjet Printer

High Quality & High Performance

Nagano, Japan (September 8, 2015)

Mimaki Engineering Co., Ltd., a global industry leader and manufacturer of wide-format inkjet printers and cutting plotters, announced today that it will showcase the new flatbed UV inkjet printer “UJF-7151 plus” at the International Graphic Arts Show 2015 in Tokyo, Japan on September 11. The market launch will commence in November, 2015.

The UJF-7151 plus delivers high quality printing while ensuring accurate ink droplet placement with the maximum printable size of 710 × 510 mm (28 × 20in).

From the beginning, Mimaki has been a leader in the development of inkjet printers. In comparison to conventional analog printing, recently, there has been a growing demand for digital, on-demand, and plate-less inkjet printing because of its ability to quickly provide high-mix and low-volume printing.

The UJF-7151 plus is the best digital on-demand printing solution for the screen printing industry. Accurate ink droplet placement is crucial for delivering high-quality printing. Thus, while ensuring accurate ink droplet placement, the UJF-7151 plus delivers high-quality printing. Moreover, the UJF-7151 is capable of printing onto Kiku-han* size which is often used at screen print factories in Japan. Furthermore, the UJF-7151 plus improves accuracy by modifying the mechanical structure of the print table and offers high-performance printing that meets the position accuracy necessary for additional printing on preprinted surfaces. Fine lines, edges, and small texts are clearly represented. In addition, double-layer printing, color printing on a white base layer. is possible.

*Kiku-han size: 636 × 469 mm (25 × 18.5 in)

The patented MFD1 dithering technology processes image data along with retaining the original image quality. The highly improved quality-control MAPS4 reduces banding and uneven color printing, achieving top-level productivity within the same product range at a maximum printing speed of 3.3 m2/h*. The new printhead comprises a continuous ink circulation system to help prevent ink sedimentation and clogged nozzles. When nozzles are clogged, the nozzle check unit (NCU) automatically detects and cleans the clogged nozzles. Furthermore, the UJF-7151 flatbed UV printer employs a nozzle recovery system (NRS), ensuring that only good nozzles are used as substitutes if clogged nozzles are not recovered after cleaning. These functions maintain constant printing and reduce waste printing due to defective nozzles.

*Print conditions:600 × 600 dpi; 4 Pass

The “UJF-7151 plus” is a “high performance UV Inkjet printer” that enables high-precision ink dot placement and beautiful printing through Mimaki’s proprietary technology and top-level productivity.

UJF-7151 plus|Product page

◎Product outlines

- Mechanical structure for high-precision printing

・Unlike conventional models, a print table moves during printing for reducing printer unit vibration.

・Two ball screws are installed on both sides of the table to facilitate its movement. - Mimaki’s superior print-image quality control technology

・Mimaki Advanced-pass system 4 (MAPS4) reduces banding and uneven color printing.

・Mimaki Fine Diffusion 1 (MFD1), a patented dithering technique, is incorporated in the Mimaki RIP RasterLink 6 software.

- Maximum 3.3m2/h productivity*

・Maximum printing speed. By reaching approximately twice the speed of previous models, it achieves approximately 2.6 times the productivity of competing printers in its class.

・The print area expands to 710 × 510 mm (28 × 20 in), enabling printing of size 636 × 469 mm (25 × 18.5 in); which is often used for screen printing.

*Print conditions:600 × 600 dpi; 4 Pass - Uninterrupted printing solutions

・Realizes high-stability printing through an ink-circulating mechanism within the head.

・”NCU” automatically detects missing jets for cleaning. When cleaning fails, “NRS” automatically sets a replacement nozzle and restarts printing. This minimizes the loss of raw materials due to missing jets and automatically continues production at high quality.

◎Main features

1. Mechanical structure achieves high-precision printing

To improve precision, modifications applied are as follows.

To reduce printer unit vibration, the print table moves during printing instead of the Y-bar. Two ball screws are installed on both sides of the table to assist with its movement. In addition, four motor-driven legs are added beneath the table to maintain horizontality when the table is lifted or lowered.

Figure 1: High precision drop landing

2. Mimaki’s print technologies for achieving beautiful printing

1) Mimaki Advanced pass System 4 (MAPS4)

Generally, swath boundaries are straight lines. Therefore, a slight misalignment between boundaries causes banding or uneven color printing. MAPS4 reduces banding and uneven color printing with blurred boundaries similar to gradation printing.

■MAPS4 applied

Banding and uneven color printing are reduced by scattering swath boundaries. Beautiful print image is obtained.

Figure 2: Illustration of MAPS4

■No MAPS4

Bandings appear on swath boundaries. Print quality is remarkably degraded because banding is recognizable on each boundary.

2) MFD1—Mimaki Fine Diffusion 1

Dithering is an image processing technique, which transforms image data for inkjet printing. Pattern and error-diffusion dithering may, however, generate particular image noise resulting in uneven color printing or tone jumps, even on a high-performance printing unit.

The newly developed RasterLink 6 software,* incorporating the patented* image-processing MFD1, reduces noises due to dithering through hybrid processing of pattern- and error-diffusion dithering, thereby enhancing printing quality.

* MFD1 is available for Version 4.0 and higher

* Patent number: 5230816

3. Maximum 3.3m2/h productivity

An array of six staggered printheads increases the printing speed and achieves top-level productivity in the same product category. The UJF-7151 plus supports effective production through high-speed printing at approximately twice the speed of previous models and approximately 2.6 times that of competitive models. Furthermore, by expanding the print area to 710 × 510 mm (28 × 20 in), it is possible to print at the size of 636 × 469 mm (25 × 18.5 in), which is often used for screen printing.

4. Reliable operating support package

Ink and media shortage, clogged nozzles, and other minor problems influence stable productivity.

The UJF-7151 plus fully supports continuous printing with reliable technologies.

1) New printhead’s ink-circulation system reduces clogging nozzles

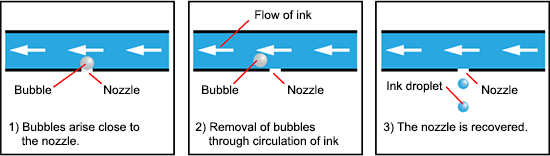

The ink-circulation system in the head reduces ink settling and thus provides stable ink jetting. In addition, this system removes air bubbles, which plug the nozzle.. Thanks to this function, the nozzle-cleaning frequency is reduced, and accordingly, cost-effective stable printing is achieved.

Figure 3 :Head Comparison

Figure 4:Self-recovery

2)NCU automatically detects and recovers clogged nozzles

Clogged nozzles are detected automatically by monitoring ink droplets with sensors. When clogged nozzles are located, these are automatically cleaned, reducing waste printing. Nozzles are checked per transfer file.

3)NRS for maintaining productivity

If the clogged nozzles are not recovered after cleaning through the NCU function, the NRS selects substitute nozzles and then restarts printing. This is a significant novelty, since previously, when nozzle cleaning fails, the printhead has to be repaired by a technician, and the printing operation ceases until the printhead is repaired. The NRS* allows the printer to continue printing without interruption by using non-defective nozzles as substitutes for defective nozzles until the technician arrives.*

*NRS may not be activated depending on print modes.

◎Specifications

| UJF-7151 plus | ||

|---|---|---|

| Printhead | On-demand piezo head (6 staggered printheads) | |

| Maximum print resolution | 1,200 dpi | |

| Maximum printable area | 710 × 510 mm (28 × 20 in) | |

| Ink | Type/Color | LH-100 (C, M, Y, K, W, Cl) PR-200 (Primer) LUS-120 (C, M, Y, K, W) * |

| Package size | 1L bottle | |

| Media | Size | 710 × 510 mm (28 × 20 in) or smaller |

| Height | 153 mm (6 in) or less | |

| Weight | 10 kg (22 lb) or less | |

| Certifications | VCCI class A, FCC class A, ETL UL 60950-1 CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH, Energy Star |

|

| Interface | USB 2.0 Hi-speed / Ethernet 1000BASE-T | |

| Power supply | Single-phase AC100 – 120V / AC200 – 240V | |

| Power consumption | 1.3kW | |

| Operational environment | Temperature: 15 – 30 °C (59 - 86 °F) Humidity: 35 – 65% Rh (Non condensing) Recommended temperature range for stable operation: 20 – 25 °C (68 - 77 °F) |

|

| Dimensions (W × D × H) | 2,198 × 1,572 × 1,273 mm | |

| Weight | 317 kg (Base stand weight is included) | |

Note: Data in the above specifications are subject to change without notice.

* LUS-120 ink will be available in the future.

◎Contact

Mimaki Engineering Co., Ltd.

Global Marketing Department

Postal code: 389-0512

Address: 2182-3 Otsu Shigeno Tomi Nagano, Japan

Tel: +81-(0)268-64-2281, Fax: +81-(0)268-64-2285