Beautiful cutting of thick materials and complex shaped rubber "The range of products that can be handled has increased, making it easier to get new jobs."

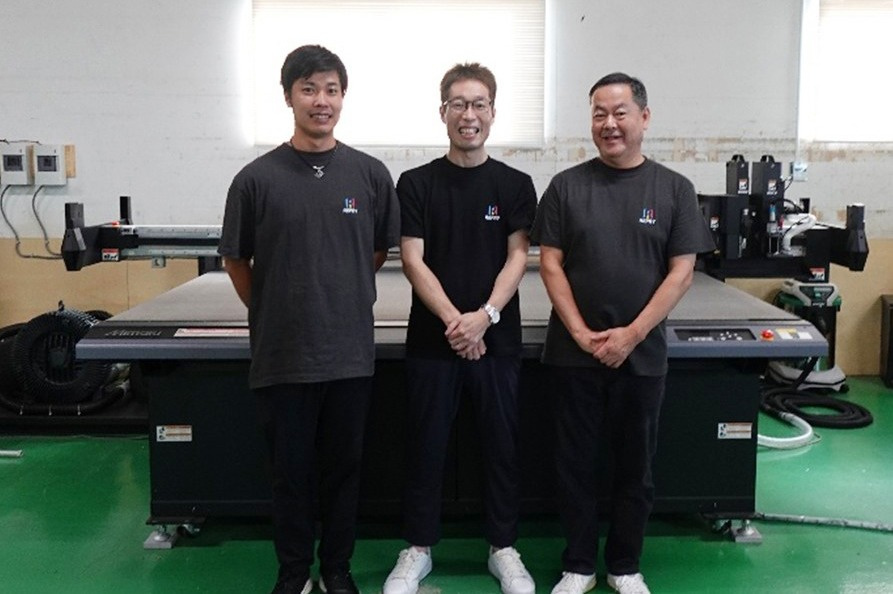

KODAMA GOMU Corp., based in Naka-ku, Hiroshima City, is a 64-year-old company specializing in rubber processing. It manufactures a wide range of rubber products. It is used for a wide range of applications, including railroad cars, airplane ladders, automobiles, medical equipment, and agricultural equipment, and annual production of more than 30000 units. He is like an "unsung hero" who supports all industrial fields. The large-format cutting plotter "CFX-2513" of Mimaki is playing an active role in such rubber processing sites. We asked the background of the introduction and the effects after the introduction.

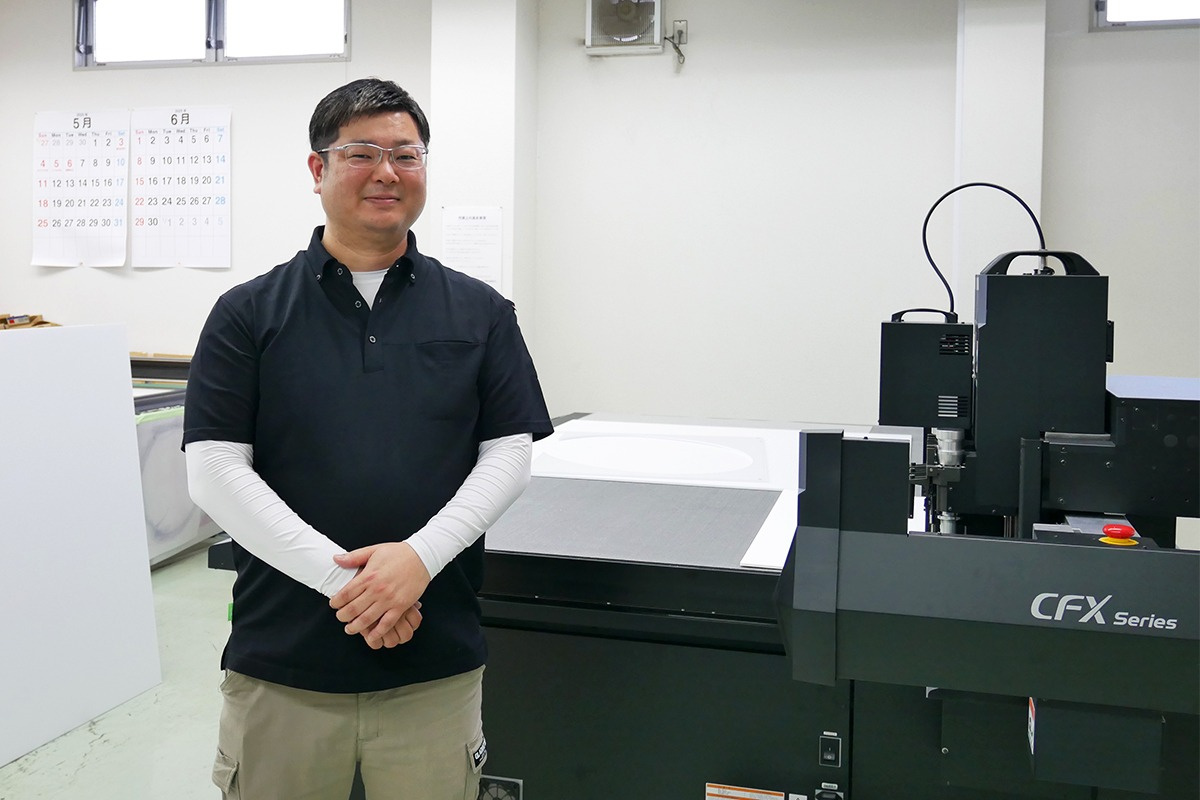

Using the CFX-2513

Cut rubber and silicon with a cutting plotter

There are two main types of rubber processing: "cutting" and "molding", and we are a company that specializes in cutting. We purchase rubber from rubber manufacturers, cut and drill holes with cutting plotters, water jet cutters and vertical cutters, and then glue them together to make products. In addition to rubber, we also process various materials such as silicone, sponge, non-woven fabric filters and films. We used Mimaki's "CFS-1313" cutting plotter for 20 years.

Processing of complex shapes depends on outsourcing to the same industry

Although CFS is good at cutting simple shapes such as squares and flanges, it is somewhat unsuitable for cutting complex designs, thick materials, and three dimensional objects. It had outsourced such products to peers with more advanced technology, but had been plagued by soaring outsourcing costs and delivery delays. The area of the table was also small, and for urgent projects, I sometimes thought, "If the table were larger, I could make it all at once." So, on the 20th anniversary of the introduction of CFS, we decided to introduce a high-performance cutting plotter that could process complex designs.

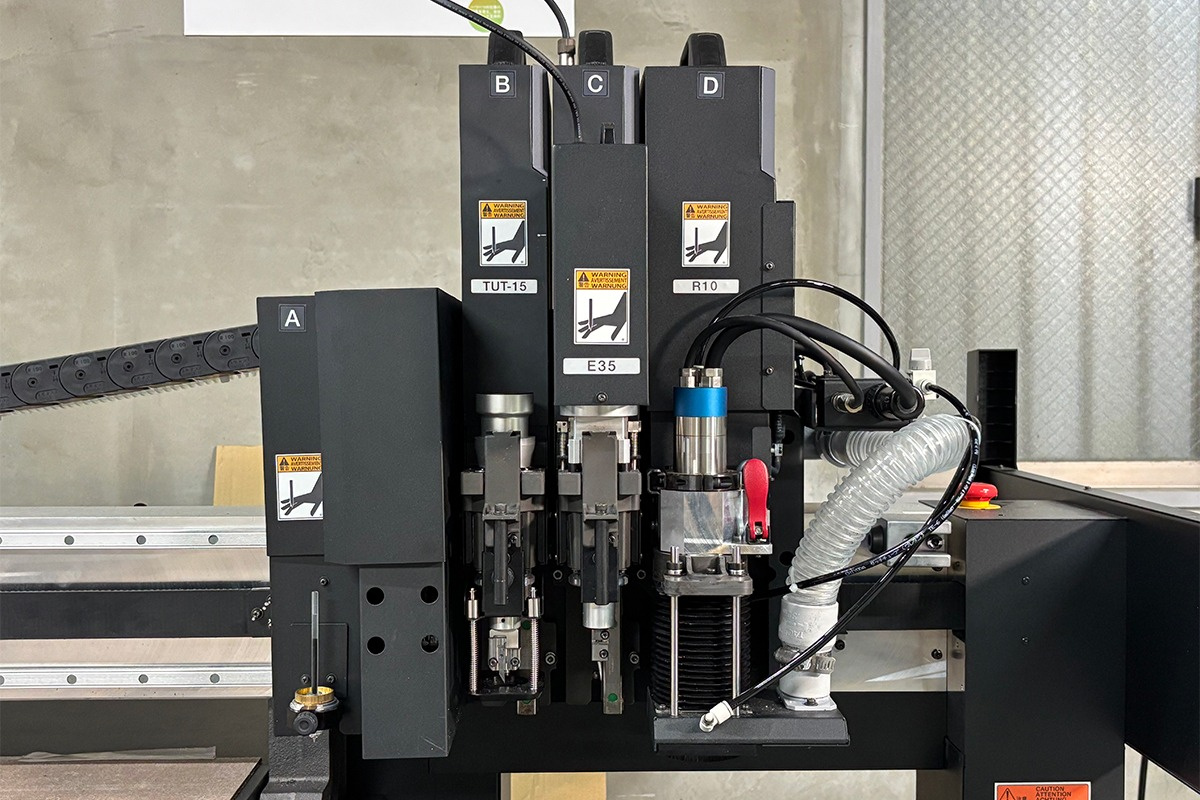

The CFX can hold up to four tools simultaneously

Sincere support and price are decisive

At present, there are many kinds of cutting plotters available from domestic and foreign manufacturers, but we had no intention of buying anything other than Mimaki's products. When we introduced CFS 20 years ago, we cut rubber by hand, and none of our employees can handle plotter-like machines. Mimaki supported such beginners for a long time until we could use the machine 100%. I had a strong impression of that time, and I thought the plotter was from Mimaki when I replaced it.

Just in case, I compared it with a cutting plotter made overseas, and the CFX won in terms of cost-performance. I think the CFX is quite reasonable for its high performance. Subsidiary aid was also used, and it was possible to introduce it with minimal initial costs.

High levels of speed, processing range, and cutting pressure

I felt the effect as soon as I started using it. The processing speed and area have been doubled, so we can make double the amount in the same time. The image is that the work that took 2 days will be done in 1 day, and the work that took 1 week will be done in 3 days.

Materials that previously could not fit on the table can now fit easily, and more often than not, they are done in one cut. When the number of cuts is reduced, the subsequent bonding process is also reduced. Bonding takes time and manpower, but with the introduction of CFX, the number of situations where bonding is required has decreased, and operators say that they now have more leeway in their work.

It is a high-end machine with high cutting pressure. It can cut the thickness and hardness that could not be cut before. For example, 50mm thick rubber and hard urethane cannot be cut well with CFS, so I outsourced it. The sponge was also crushed during cutting and could not be processed into a complicated shape, so we asked a partner company to do it. Since the introduction of CFX, all of these have been produced in-house. Now, 30% of the products that were outsourced have been produced in-house, which directly leads to cost reduction and shortening of delivery time. Eventually we will be able to reduce the amount of outsourcing by half.

Cutting about 5 cm thick rubber with CFX.

The mere presence of CFX increases sales

The number of compatible materials has increased and the delivery date has become speedy, so it has become easier to get a job. We are now able to actively accept projects that were previously rejected due to delivery time and cost.

We are introducing CFX as our equipment on SNS and Website, but there are regular inquiries that want to see the actual machine, which sometimes leads to an order. This is the first time that just having a machine leads to sales.

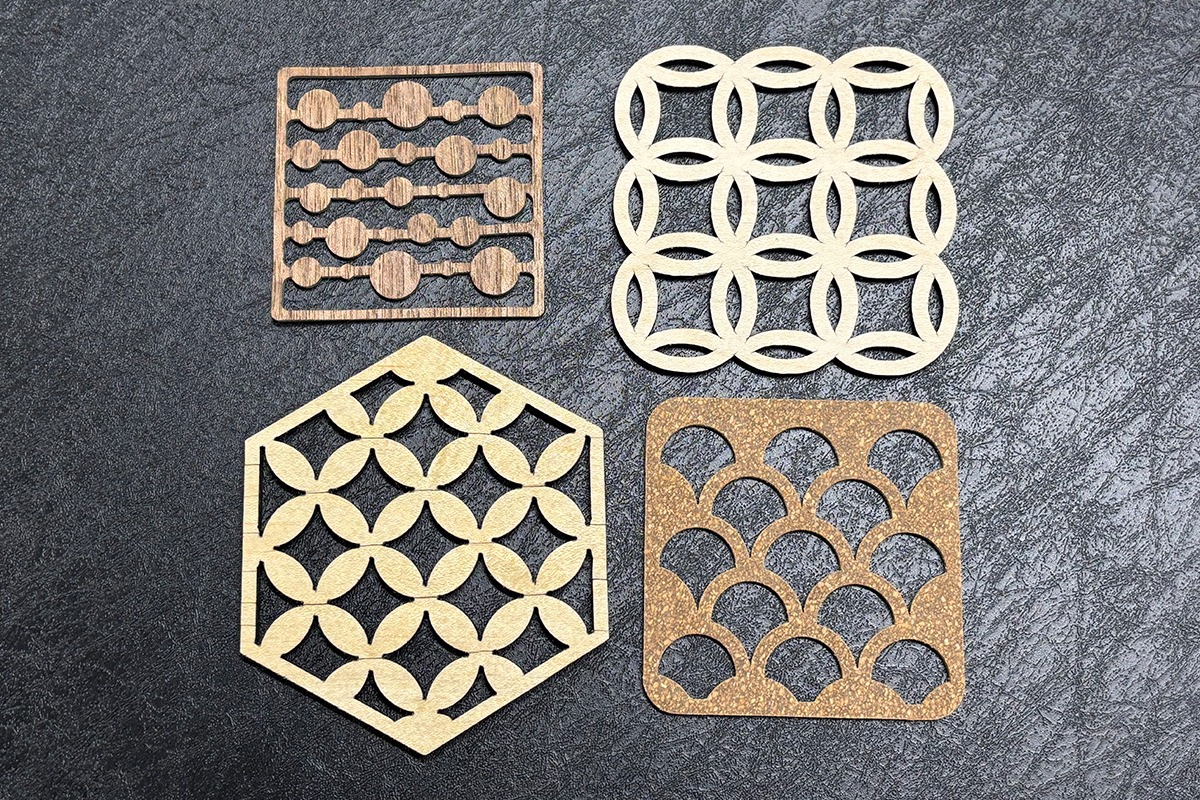

It is also used for making goods with stylish designs.

At present, we are using CFX to engage in an "up-cycle business utilizing scrap materials." Coasters and coin purses are made by combining rubber scraps from our manufacturing process and natural wood chips (thinly sliced wood) scraps from other companies. CFX can make layers of rubber and wood, and express fine and fashionable designs. It motivates me to make it.

For more than 60 years, we have been doing only BtoB work, making parts based on drawings given by customers. I've always wanted to start a new business, but I've put it on the back burner because I was too busy with the main business. But with CFX, I can now afford to work on a new business: making consumer goods. Another positive effect was the creation of conversations within the company about what to make next, creating an exciting and lively atmosphere.

Coasters made from scraps made with CFX

User profile

- NameKODAMA GOMU Corp.

- IndustryProcessing of rubber, silicone, sponge, film, etc.; material proposals; wholesale; upcycling business utilizing scrap materials

- Address3-3 Kawara-machi, Naka-ku, Hiroshima, Japan

- Phone number+81-82-232-1418

- URLhttps://kodama-gomu.com/