A case study of TOKYO HYOSHIKI Inc. installing our JV100-160 was featured in the “Voice from the Inkjet Output Field 2021” on the “Signs&Displays” monthly magazine (August 2021 issue) for the outdoor /transportation advertising industry.

The following is the published article in its original form.

Click here for the original article PDF

We can continue stable output operations even during the coronavirus pandemic.

TOKYO HYOSHIKI Inc. offers a wide range of services, from the sale, lease, and installation of construction security products to the production and installation of road signs, road markings, and guide signs, as well as the planning, production, and installation of indoor and outdoor signboards for stores, commercial facilities, and general buildings. A large part of the company's business is the production of signboards for construction sites, and the coronavirus pandemic has not had a major impact on its sales. Here, we look at the reasons for this.

Production has been continually requested by customers who have been familiar with the company since its establishment

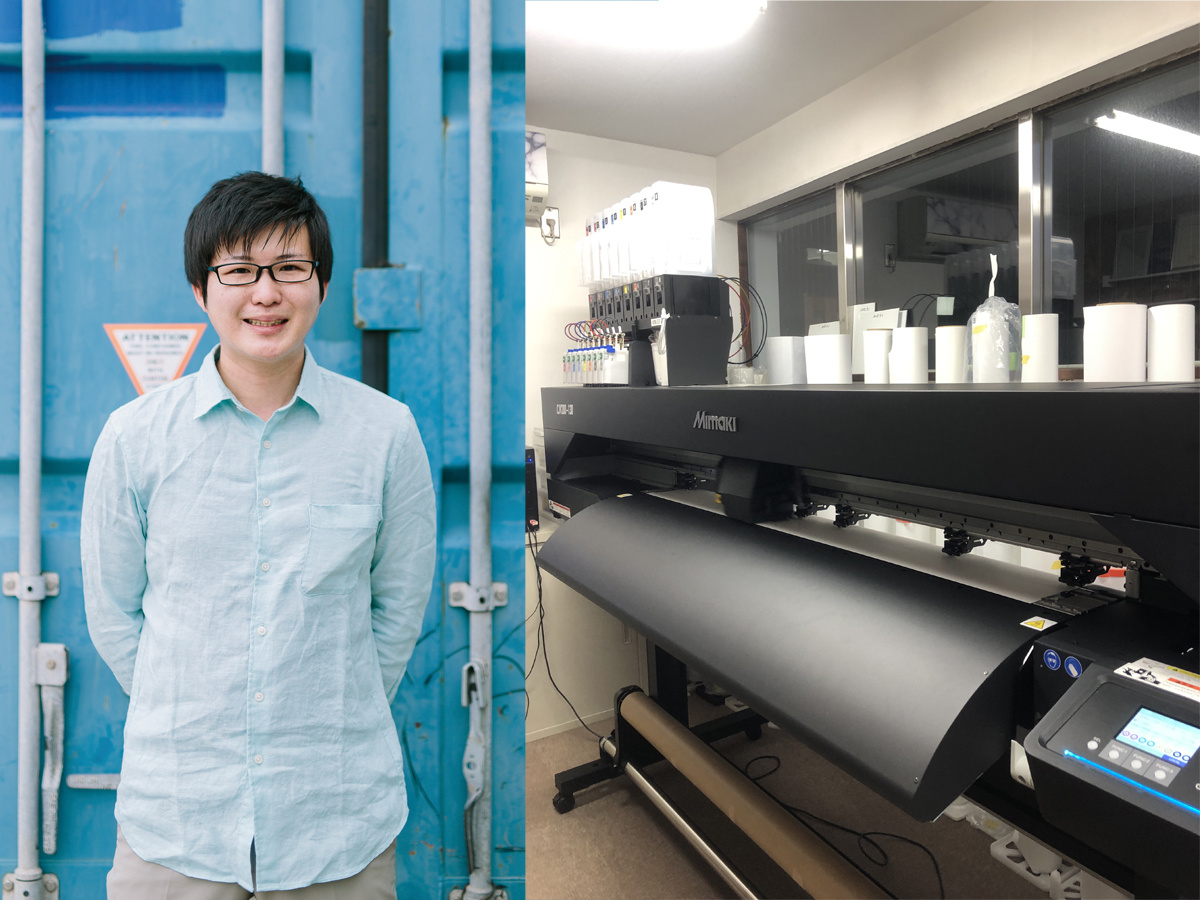

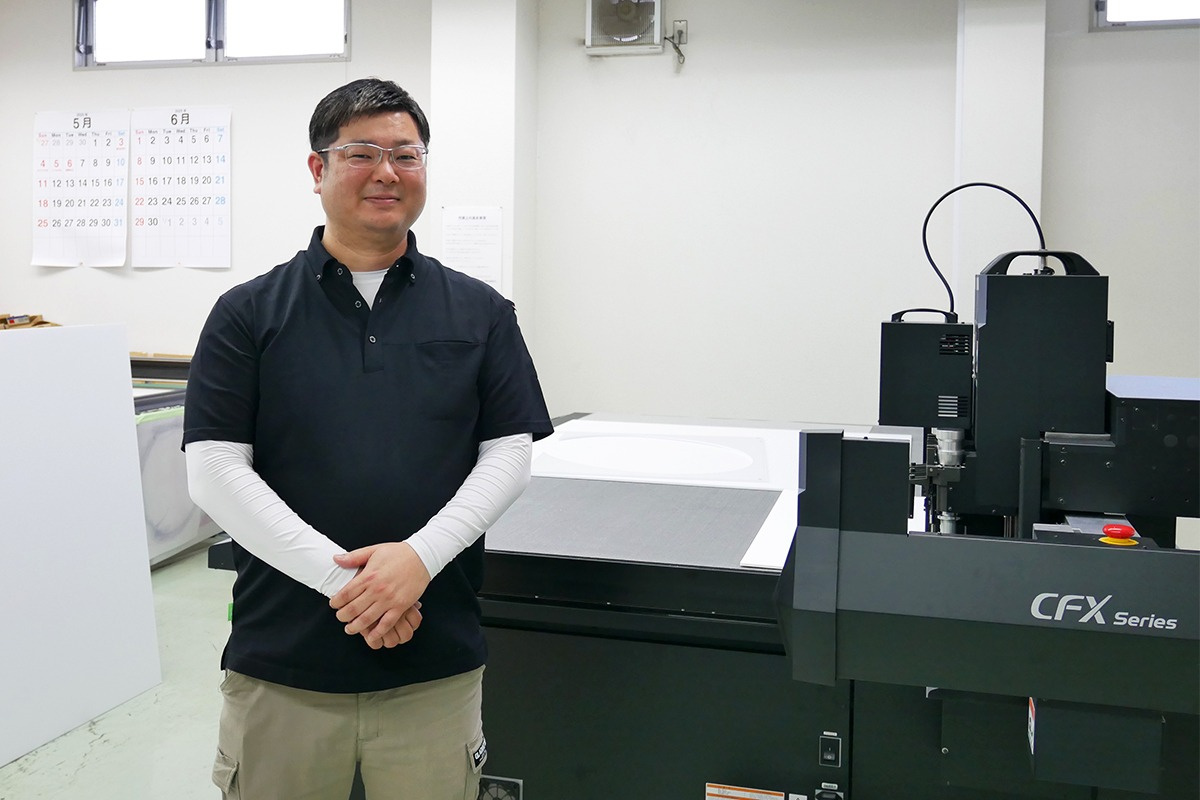

Mr. Setoi (left) and Ms.Takahashi, TOKYO HYOSHIKI

“Since its establishment in 1968, the company has been producing signboards for construction sites, mainly in Tokyo and Kanagawa. Most of our customers are companies that we have known for more than 50 years, and we have strong ties with privately owned companies rather than major ones, and we have been receiving work from them on a continuous basis,” says Ms. Yukiko Takahashi, Planning & Production Department of TOKYO HYOSHIKI. Currently, the company deals with several hundred companies. About 100 of them request the production of signboards about three times a week.

The company now uses two “JV100-160” inkjet printers by Mimaki Engineering Co., Ltd. (hereinafter “Mimaki”) for signboard production. They were installed in June this year; one at its head office (Tokyo) and one at its Tsukuba branch.

JV100-160 is a roll to roll eco-solvent inkjet printer that supports Mimaki’s new quick-drying solvent ink “AS5”. The appealing feature of this printer is high operability, which makes it easy to use even for those who are not yet skilled in printer operation. The printing speed is improved by 180% compared to the previous model (JV150), achieving a productivity of 20.0m²/h (for high-speed mode 720 x 600 dpi, four-color print).

The head office of TOKYO HYOSHIKI uses the JV100-160 to output about 100m² per month. “Because cost and speed are important to us, we chose this printer based on how much we can print in a day,” says Mr. Kazuki Setoi, Planning & Production Department of the company, of the reason for introduction. “When I actually used it, I was impressed by the much more vivid colors. And the function that automatically cuts printed sheets is very helpful. This is something I do every day, so it would be hard to do it manually.”

TOKYO HYOSHIKI used to use Mimaki's solvent ink “SS21” (440 cc cartridge), but switched to “AS5” (2L bulk ink) at the suggestion of Mimaki when it introduced the JV100-160. The price of “AS5” is about half of that of “SS21” (17.6 yen/1 cc), so the company has succeeded in reducing the ink cost.

“I used to worry about the ink level all the time, but bulk ink gives me peace of mind,” says Ms. Takahashi. “The ink has become inexpensive, but the quality has not declined; on the contrary, I think it has become better,” says Mr. Setoi with a content tone.

“JV100-160” uses the “AS5” ink. It also adopts a bulk ink supply system (2L) that handles everyday output work. In addition to the production-oriented four-color model, this machine can also respond to eight colors.

![TOKYO HYOSHIKI uses the JV100-160 in a slightly different way. They use different rolls (1,000 mm wide for construction site signs and 1,300 mm wide for other purposes) depending on the data. In addition to the regular roll, one roll is set in front of the JV100-160 and another roll on the take-up reel, for a total of three rolls ready for use, to shorten the operation time. [* Originally created by TOKYO HYOSHIKI]](https://d2w577gk9zpoty.cloudfront.net/archives/143/202109/e4c5c0130b4cd04b57df3647d3c59239553480ff77a4f07c700e8efbec7d1f5d.jpg)

TOKYO HYOSHIKI uses the JV100-160 in a slightly different way. They use different rolls (1,000 mm wide for construction site signs and 1,300 mm wide for other purposes) depending on the data. In addition to the regular roll, one roll is set in front of the JV100-160 and another roll on the take-up reel, for a total of three rolls ready for use, to shorten the operation time. [* Originally created by TOKYO HYOSHIKI]

In the future, we will also produce signboards with graphics and photos

People say that many signboard shops have suffered a substantial drop in sales due to the effects of the new coronavirus. However, TOKYO HYOSHIKI has seen no significant change in sales because its core business is to produce indispensable signboards for construction sites, and because there are many old, familiar customers.

“In the early days (of the coronavirus outbreak), there were times when construction work was delayed, and we lost some work because of that, but since then, construction sites have been active, so our sales have hardly dropped at all,” says Mr. Setoi.

Signboards for construction sites produced by TOKYO HYOSHIKI using JV100-160

The fact that the company has many regular customers can be understood from the way the company usually deals with them. The company's usual delivery time is three days. However, in urgent cases, such as when they really need the product tomorrow, the company tries to accept the request as much as possible. In fact, such a request has never been turned down in the past, they say.

“Right now, we mainly produce signboards for construction sites, but in the future, we would also like to produce signs with more graphics and photos. We hope to expand our business even little by little, not limiting ourselves to construction sites. I’m going to tell our sales staff more about the fact that we can also produce such signs,” says Mr. Setoi with enthusiasm.

User profile

- NameTOKYO HYOSHIKI Inc

- IndustrySale, lease, and installation of construction security products, production and installation of road signs, road markings, and guide signs, planning, production, and installation of indoor and outdoor signboards for stores, commercial facilities, and general buildings

- Address2-14-10 Kamiigusa, Suginami-ku, Tokyo, Japan

- Phone number+81-3-3395-3315

- URLhttp://www.tokyohyoshiki.co.jp/