UJV100-160Plus | Product information

Nagano, Japan, September 19, 2023

Mimaki Engineering Co., Ltd. (Head office: Tomi-shi, Nagano, Pref.; President: Kazuaki Ikeda), specializing in industrial inkjet printers, cutting plotters and 3D printers, is to announce the release of “UJV100-160Plus”, and entry model UV-curable inkjet printer that has achieved further evolution with low power consumption and three additional functions for sign graphic printing applications, and will begin worldwide sales at the end of October 2023.

In recent years, energy prices have continued to soar due to the global energy demand crunch. In particularly, Japan, Germany, and other developed countries rely heavily on energy supplies from overseas, so the impact of energy prices hikes on economic activities in significant. Soaring energy prices can directly lead to lower profits and loss of price competitiveness in corporate activities, so companies are required to use energy more efficiently.

Efficient energy use reduces CO2 emissions in addition to its cost. As environmental protection and climate change measures driving the introduction of CO2 emission laws and regulations in many regions, consumers are becoming increasingly concerned about the environment and are more supportive of environmentally friendly products and services. Companies‘ efforts to reduce CO2 emissions will be a way to gain the support of their customers and improve their market competitiveness.

In the sign graphics market, eco-solvent printers using solvent inks, water-based latex printers, and UV-cured printers are widely used. Among these, eco-solvent printers and latex printers consume relatively high amounts of electricity because they require ink drying with heat, which directly affects the electricity cost burden of print businesses.

With a maximum power consumption of 0.5kW, the “UJV100-160Plus” consumes approx. less than 20% power of eco-solvent and latex printers in the market*, helping print businesses reduce power costs and CO2 emissions.

*Company research

The “UJV100-160Plus” has the basic functions of the conventional “UJV100-160” with three additional functions to expand the range of applications for customers, reduce running costs, and improve work efficiency.

Three additional functions

(1) Ink saving function to reduce running cost

(2) Maximum 3-layer printing function to expand the range of applications

(3) Improve work efficiency due to improved linkage with Mimaki’s cutting plotter

The UJV100-160Plus is the definitive entry model for sustainable sign and graphic printer, with low running costs, versatile expression, and easy printing for everyone. The UJV100-160Plus is expected to sell 1,000 units per year (worldwide).

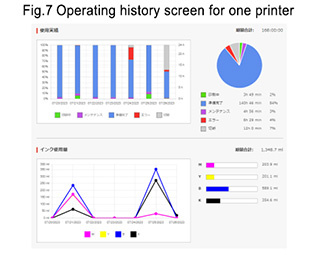

With the release of the UJV100-160Plus, we will launch “PICT”, a cloud-based printer status monitoring tool, available for download from our website for customer using Mimaki printer products. “PICT” supports customers in improving the efficiency of their printing operations and production management by enabling them to visualize the operational status and performance of their printers from a PC or mobile device, even from a remote location.

Features of PICT

1. Provided by downloading from Mimaki’s website and it can be used on PCs and mobile via web browser.

2. Visual status of all printers in the fleet improves work efficiency.

3. The printer operation and ink usage results are visualized for each printer and designated groups, which is useful for maintenance planning, ink inventory management, and production planning.

Mimaki Engineering Co., Ltd. with its management vision of “Something New, Something Different,” will continue to pursue new technological innovations to achieve the “beauty and speed” that our customers demand.

Outlines of the press release

- The entry model UV printer “UJV100-160Plus” with approx. less than 20% of power consumption (compared to latex printers and eco-solvent printers in the market) and “three added functions” will be launched worldwide at the end of October 2023.

- Function 1. “Ink saving function” to reduce ink consumption for printing with simple operation.

- Function 2. “Pull-back printing function” allows up to 3-layer printing for a wide variety of expressions.

- Function 3. Seamless linkage with Mimaki’s cutting plotters improves workability and productivity.

Primary features

1. Ink saving function to reduce running costs

Reduces ink consumption by up to 50% while maintaining the color balance of the printed design. Ink reduction levels can be set with simple operations of print software “RasterLink7”, so there is no need for specialized knowledge or equipment for color adjustment.

2. Multi-layer printing function to expand the scope of print application.

The “pull-back printing function”, which pulls back the printed substrate for follow-up printing, supports up to three-layer printing.

Conventional printers support up to two-layers printing, but it was necessary to determine whether to print white to colors or colors to white when the printer was installed.

The UJV100-160Plus has a newly added pull-back printing function that enables printing of both methods regardless of the ink color array. In addition, three-layer printing as shown ink (1) and (2) below provides printing application and added value.

(1) Colors - White - Colors: Applied to brightly colored backlit signage day and night

(2) White - Colors - Clear: Applied to window graphics with a variety of expressions

3. Seamless linkage with Mimaki’s cutting plotter improves work efficiency

Conventional labels and stockers are produced by printing on a substrate and then using our cutting software ”Finecut9”. And output the cut data. Now, it is possible to output cut data directly from “RasterLink7” to Mimaki cutting plotter “CG-AR series”, improving the work efficiency of operators in cutting operations. This enables linking of printing and cutting even if the output PC does not have design software.

4. Cloud-based print status monitoring tool “PICT”

(1) Visual display of printer operating status, allowing you to see at a glance which printers are available

(2) Visualization of printer operation and ink usage by individual printer and by group

5. Support functions that enables anyone to print stable, high image quality (Same functions as previous models)

(1) Automatic dot position and feed correction function:DAS (Dot Adjustment System)

(2) Smooth printing by reducing color irregularities and glossy streaks:MAPS (Mimaki Advanced Pass System)

(3) Automatic nozzle detection (NCU:Nozzle Check Unit) and recovery function (NRS:Nozzle Recovery System)

Automatic detection and cleaning of defective nozzles prevents material loss. Even if the defective nozzle is not recoverable, output can continue without waiting for service personnel to arrive and without reducing productivity. Your work will not be interrupted.

Product specifications

| Items | UJV100-160Plus | ||

|---|---|---|---|

| Print Head | On-demand piezo head | ||

| Print resolution | 360dpi, 720dpi, 900dpi, 1200dpi | ||

| Ink | Type/Color | UV curable ink LUS-170 / C,M,Y,K,W,CL (Clear) UV curable ink LUS-210 / C,M,Y,K,W,CL (Clear) *1 UV curable ink LUS-190 / C,M,Y,K,W,CL (Clear) *1 | |

| Capacity | 1L bottle | ||

| Maximum printout width | 1,610 mm (63.4 in) | ||

| Media | Maximum width | 1,620 mm (63.8 in) | |

| Thickness | 1.0mm or less | ||

| Roll weight | 45kg (99.2 lb) or less | ||

| Interface | Ethernet 1000 BASE-T, USB2.0 Hi-Speed | ||

| Power Specifications | AC100~120V/200~240V±10% 50/60Hz±1Hz | ||

| Power consumption | Max. 500W or less / Min. 4.5W or less | ||

| Safety Standard | VCCI ClassA, FCC ClassA, IEC 62368-1 ETL, CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH, Energy Star, RCM, EAC | ||

| Dimensions (W x D x H) | 2,775mm x 700mm x 1,475mm (109.3 in x 27.6 in x 58.1 in) | ||

| Unit weight | 167kg (368.2 lb) | ||

*1 Only available in specific countries/regions

*Specifications, designs, dimensions, and other information stated in this list may be subject to change without notice due to technical improvement etc.

About Mimaki Engineering

Mimaki Engineering develops, manufactures, sales, and maintains industrial inkjet printers, cutting plotters, 3D printers, inks, and software. By providing total solutions for the printing process for the sign graphics, industrial products, and textile apparel markets, we aim to be an innovator that constantly delivers "Something New, Something Different" to our customers.

Company/IR website: https://ir-eng.mimaki.com/

Product website: https://mimaki.com/

Contact

MIMAKI ENGINEERING CO., LTD.

Global Marketing Department

1628-1 Shigeno-Otsu, Tomi-city, Nagano 389-0512 JAPAN

Tel: +81-(0)268-80-0078 / Fax: +81-(0)268-80-0041