Select your region×

Japan

Europe

Asia Oceania

North America

South America

Case Study

Challenges

Improvements

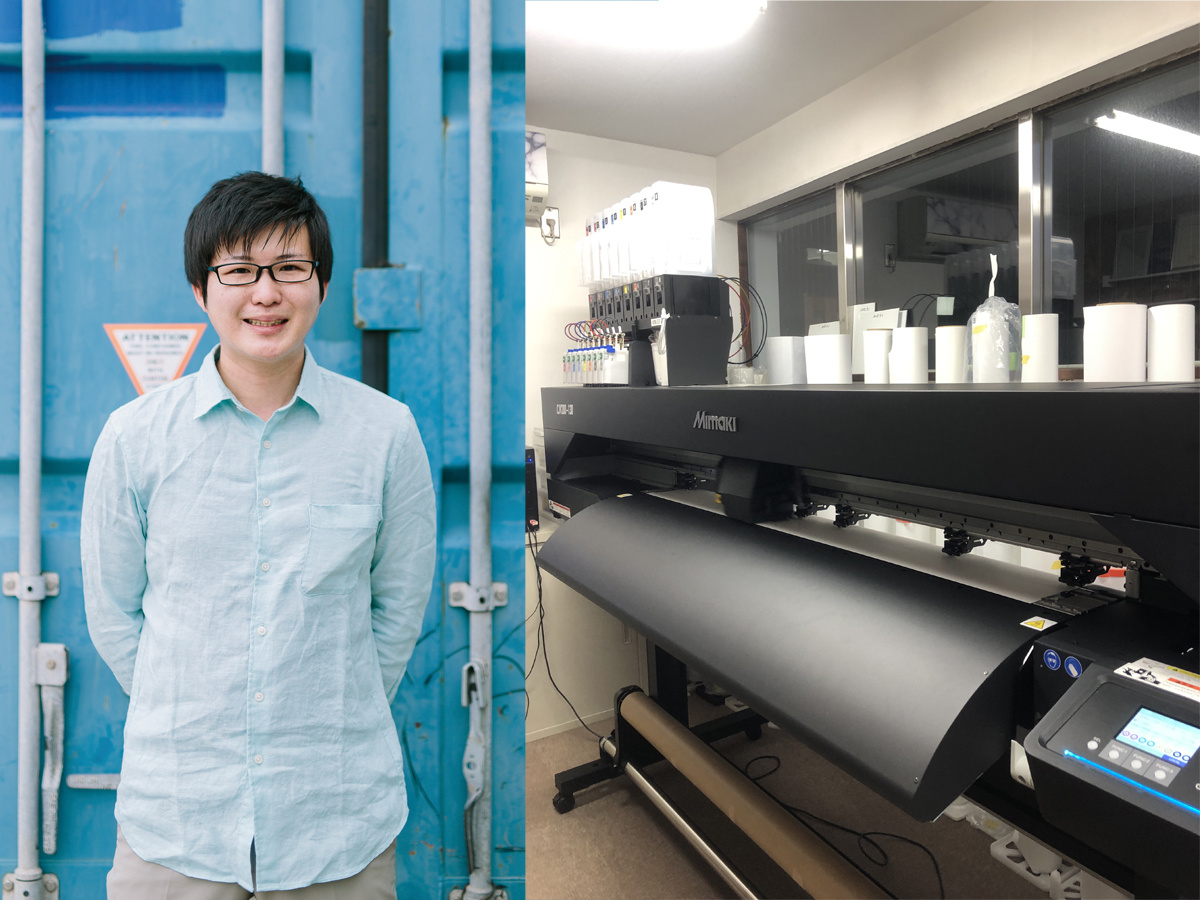

At SAN GRAPHICA Inc., while the "CJV300" had delivered high-quality printing, the expanding range of production materials necessitated more stable high-resolution output and improved workflow efficiency. Additionally, the ability to operate within limited installation space and the ease of operation and manageability even with a small staff were key points when considering equipment upgrades.

The introduction of the "CJV200" maintains the same high image quality while further improving color reproduction and detail stability. Its compact size and simple operation allow it to fit seamlessly into any workspace, streamlining daily tasks. Furthermore, low-odor ink and a system for monitoring operational status create an environment where even small teams can operate with confidence.

Product installed

Challenges

Improvements

Entering the sign market to expand their business base, they wanted to have machines from a manufacturer that can provide everything in-house and has a proven record.

Both speed and quality were much better than expected, and the colors were outstanding. They have never had a machine that prints so smoothly, including the feel of operation. Generous support at the employee level within the company allows us to use the machine with peace of mind.

Product installed

Challenges

Improvements

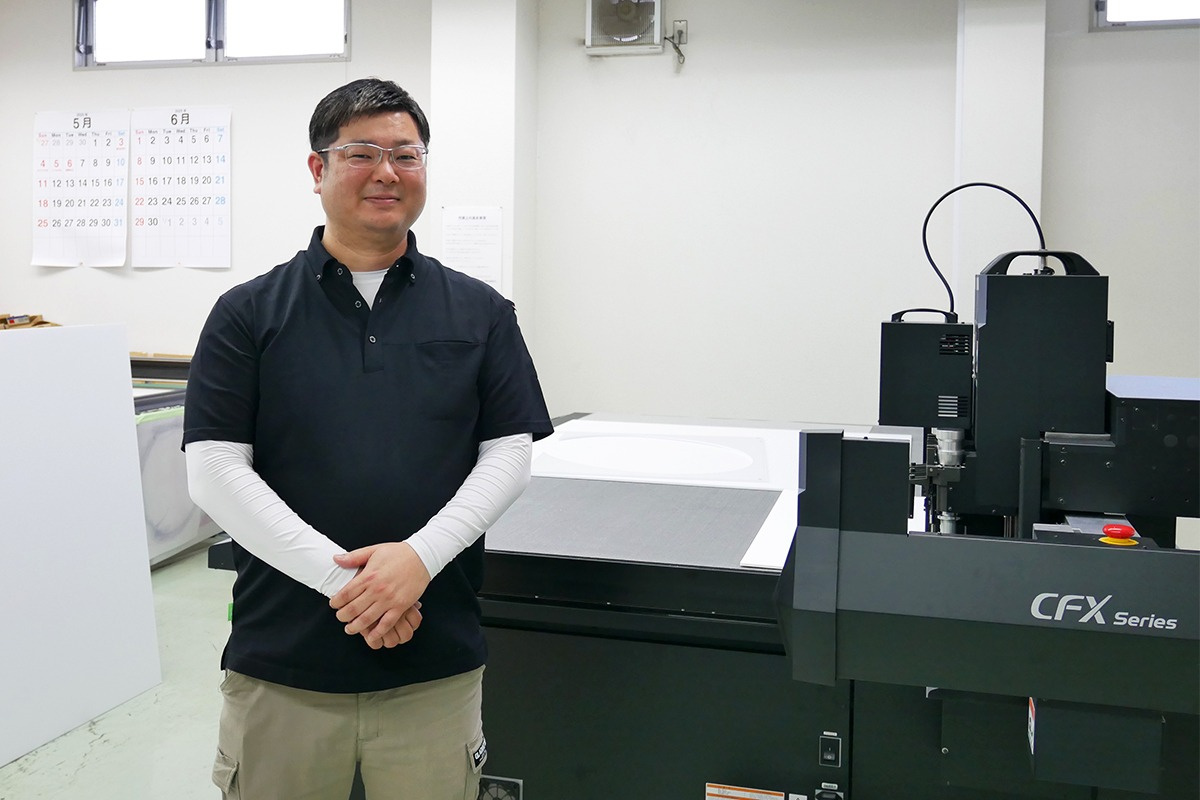

The amount of orders for deformed floor seats and life-size panel production is increasing year by year and overtime is a matter of course in the busy season. They wanted to automate the process of cutting large base materials, because there were some cases where the site was overcapacity at times and they had to turn down jobs that our sales staff had won.

Reduced the dependency on individuals of the work and labor costs have been reduced by about 15% since the introduction of CFX. Even during the peak season, they were able to get through without overtime and without turning down a single job. In addition, the defect rate was improved, and the introduction of additional equipment was considered only three months after the introduction.

Product installed

Challenges

Improvements

The JV300 they had been using for many years had been deterioration and they wanted to replace it with a printer with higher specifications.

Satisfied with the output speed and density of white ink. Printing speed does not slow down even when printing with more passes than before, and the results are clear and beautiful. The JV330's new "Media Changer" feature is fully utilized to greatly increase productivity.

Product installed

Challenges

Improvements

Need a machine with high productivity and high cutting accuracy for apparel applications.

When they were using other companies' machine, they experienced cutting discrepancies or lack of cutting, but the CJV150 covered all the problems. The vividness of the colors is highly evaluated by customers, and they are also satisfied with Mimaki's support system.

Product installed

Challenges

Improvements

The two started a sign production company. They wanted to purchase a machine that can produce high quality work with low initial cost in a short period of time as soon as possible after starting a business.

Using a campaign, the company purchased printer, a laminating machine, and a cutting plotter while keeping costs down. The machine was delivered within two weeks after the order was placed, and after installation, they were able to get one-shot OKs from customers who are particular about color. The range of work has also expanded, and they would like to increase work related to exhibitions and events, where they are strong.

Product installed

Challenges

Improvements

The color reproduction of solid colors was not stable, and they were considering replacing a competitor's machine. When outputting large signboards, the joints were noticeable, and the company had received complaints.

JV330-130 can print beautiful colors from strong shading to light feminine colors, such as solid red. Image quality is also perfect, and work efficiency has been improved by 1.2 times while quality has been improved.

Product installed

Print cooperation for Shirai Yumie's exhibition "Wriggling, Breathing and Rolling"

Collaboration

Efforts of Mimaki

Artist Yumie Shirai, Chikuma City Art Machikado Gallery

We cooperated with the printing of fabric and outdoor soft signage for the venue's spatial presentation.

Product used

Collaboration

Efforts of Mimaki

Photographer: Kodo Chijiiwa

We have conducted printouts of the exhibition works using "JV330-160" and "TS330-1600".

Product used

High reproducibility to express colors that could not be produced before: Nakagawa Chemical Inc.

Challenges

Improvements

Need a multicolor machine with high reproducibility of works.

Introduced "JV330-160" equipped with 8 colors including orange and light black. In addition to high reproducibility, the speed of finishing, stability of operation, and ease of use of the RIP software were highly evaluated.

Product installed