1. Abundant features that achieve Mimaki quality

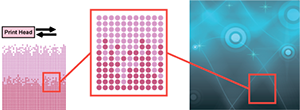

DAS (Dot Adjustment System) NEW!

The JV100-160 is equipped with the DAS, a function to automatically adjust the dot position and feeding amount that affect print quality.

When media or printing conditions are changed, an adjustment of ink dot position and media feed amount to suit is necessary.

As the DAS automatically performs these operations, printing can be performed without any labor or variations in adjustments by the operator.

Mimaki technology that enables stable and high-quality print

MAPS4

Generally, swath boundaries are straight lines. Therefore, a slight misalignment between boundaries causes banding or uneven color printing. MAPS4 (Mimaki Advanced Pass System 4) reduces banding and uneven color printing with blurred boundaries similar to gradation printing.

MAPS ON

Banding and uneven color printing are reduced by scattering swath boundaries. Beautiful print image is obtained.

MAPS OFF

Bandings appear on swath boundaries. Print quality is remarkably degraded because banding is recognizable on each boundary.

NCU & NRS automatically detects missing nozzles and performs recovery

NCU (Nozzle Check Unit) detects the status of nozzles automatically. When the NCU detects a missing nozzle, it automatically performs cleaning. If cleaning does not solve the problem, NRS (Nozzle Recovery System) automatically replaces the defective nozzles with other nozzles, which enables users to continue the print operations without waiting for a repair by a technician.

2. High productivity

Prints out 180% faster than JV150 *

High productivity supported by high functionality allows for more order processing of short-duration work.

*JV100-160: 20.0m²/h JV150-160: 11.1m²/h (Media: PVC, Y resolution: 720dpi 6P)

Print Speed

3. Stable quality is achieved with eco-solvent ink with an excellent drying property

New AS5 and CS250 inks with excellent drying properties are used

New ink boasts excellent safety and high quality, which is evaluated by waveform created by a printer manufacturer. One of the features is upgraded drying property.

It evaporates quickly after printing and print-outs dry much faster, which prevents blocking and enables reproducing in detail even images that need a lot of ink.

4. New and improved genuine RIP [RasterLink7] is provided as standard

RIP core modified to enable high-speed PDF processing, improving processing speed by 25% on average. Increases productivity.

RasterLink7 | Product information

JV100-160 Catalog (3.31MB)

Model

| JV100-160 | Maximum print width: 1,610 mm (63.4") [Cartridge type] [Bottle type] |

|---|

Corresponding Ink

Application list

- Sign & Display

- Window Graphics

- Banner

- Poster

- Vehicle Wrapping

- Wallpaper

- POS Display

Application

Case Study

- One of the best sign and display business startups. JV100-160 approaches overwhelming cost performance: N's Sign Co., Ltd.

- Mimaki sponsored the Kodo Chijiiwa Photo Exhibition "JŪRA YURA" Commemorating 100 Years of Diplomatic Relations between Japan and Lithuania.

- Working beyond the field of sign/display brings new knowledge and expertise. Voices from Inkjet Output Sites, 2022 - Signs and Interiors Production: Central Co., Ltd.