Eco-friendly water-based ink

Latex ink (LX101, LX100)

Our water-based “MIMAKI Latex ink” have very little VOC’s (volatile organic compound) and does not need special ventilating equipment. This eco-friendly ink reduces the operator’s health load and is better for the environment.Latex ink

Wide gamut is achieved

Thanks to the new orange and green inks, LX101 ink covers 93% of approximate Pantone color chart with high reproducibility of color gamut that cannot be achieved by 4 color printing.

Taking advantage of high color reproducibility, an application range is widely extended to POP/posters for company logos and proofing of package designs that are mostly specially designed.

The World’s First White Latex Ink

White ink helps retain the natural vividness of colors by being used as a base to print on transparent or colored materials. It is very effective in the manufacture of clear film window graphics etc.

Ink circulation,ecology & economy applications of white ink

MCT (*) to regularly circulate white ink is standard equipment. It enables stable output from the time of machine startup by effectively avoiding the settling of white pigment in the ink lines. Additionally, MCT contributes to reduction of ink waste, thereby supporting environmentally and economically friendly applications.

* MCT = Mimaki Circulation Technology. MCT works only with white ink.

Color mode selectable to your needs

Eight ink cartridges can be inserted and you can choose the color configuration of ink at the time of installation. If a 5-color mode (CMYK+ white) is selected white ink is added, but for higher productivity, such as bill board printing a double CMYK 4-color mode can be selected for higher productivity.

Window graphics are printed with transparent PET film. White Latex makes colors vivid!

Three-layer printing at one time

A three-layer printing of color, white and color can be performed at one time.

The underlay printing of a base layer of white ink allows reproduction of the natural beauty of colors printed on transparent media in perfect registration.

Excellent usage for outdoor and indoor applications

Latex ink fixes pigment to media because resin contained in the ink dissolves with the heater, forming membrane. Therefore, it can be outputted on PVC film, banner material, backlit bluebacked paper indispensable for sign making and on most media that are currently used in eco-solvent machines. Moreover, non-coat media without acceptance layer, such as paper and textile, can be printed as well. This excellent media capability is very attractive as it supports new applications and can expand future print business.

60℃ cold cure expands capability for various heat-sensitive media

It can be used to output on heat deformable or discolorable materials including PET, it also contributes to reduction of color blurring due to high temperature. Combining its excellent media capability with cold cure, Latex Ink can meet the diversified needs of clients in a finer, more versatile and higher quality manner.

* Depending on media, ink curing temperature needs 70℃ or higher.

No drying time, Immediate secondary processing

When using Mimaki Latex inks, fixation and curing is immediate. It is therefore not necessary to worry about drying times. Immediately after printing, secondary processing, such as lamination, can be performed, dramatically increasing time and efficiency.

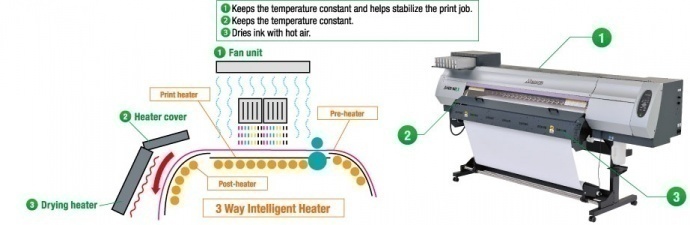

Improved drying device for the color reproduction fixability of ink

3 Way Intelligent Heater improves the color reproduction and fixability of ink by heating the media to the proper temperature before, during and after printing. In combination with the 3 Way Intelligent Heater, the added drying heater is employed to help resin dissolve to form a membrane.

Newly developed high-speed print heads

Two newly developed print heads with four rows of 320 nozzles per head are arranged in a single line, enabling high-speed printing with top quality results.

JV400LX Print speed

*Print speed of white ink(Standard mode): 1 layer (White ink only) 3.3㎡/h , 2 layer (White+ Color) 1.9㎡/h , 3 layer (Color+White+Color) 1.4㎡/h

High quality prints are made available by advanced technology

Variable drop sizes with minimum size of 4 pl

Variable drops function provides 3 different drop sizes at once. The minimum size is amazingly 4 pico-litter drop and produces smooth and natural gradation, without granular appearance even in the 4-color mode.

Fail-safe features for continuous operation

Nozzle Recovery Function

Without the nozzle recovery function, when printing and nozzle clogging or failure occurs that could not be resolved by the nozzle cleaning function, printers have to wait stop until the Mimaki service team arrives. When it comes to this function, even if nozzle washing has no effect on a troubled nozzle, the print image quality can be retained immediately without slowing down the print process.

* The recoverability of this function is limited.

UISS (Uninterrupted Ink Supply System)

Two ink cartridges per color can be set in 4-color mode. When an ink

cartridge runs out, another cartridge of the same color automatically starts

supplying ink, preventing the printer from stopping while producing large

volumes of output. This feature is especially useful for unattended overnight

printing,

Eco-cartridge method

Eco-cartridges can be repeatedly used by changing spent ink packs. This eco-cartridge method contributes to waste reduction and can provide ink at lower prices.

* 1: Ink pack capacity is 600 ml.

* 2: LX100 white ink is for 220 ml ink cartridge.

JV400LX Series Catalog (3.38MB)

Model

| JV400-130LX | Maximum print width: 1,361 mm (53.6") |

|---|---|

| JV400-160LX | Maximum print width: 1,610 mm (63.4") |

Corresponding Ink

Application list

- Sign & Display

- Window Graphics

- Poster

- Vehicle Wrapping

- Wallpaper

- POS Display