High production - High speed printing of up to 8.0m²/h

The CMYK staggered (4C+4C) setting can be selected without special colors, primer or clear, to achieve print speeds approximately twice as fast as conventional machine.

Printhead Configuration: High productivity and high image quality are realized by installing 8 heads, 2 more than the current model.

For a 8-printhead configuration, two set-ups are available: 6+2 stagger (6C+2SP) or 4+4 stagger (4C+4C/4SP).

The 6-color configuration, including the newly added light colors (Lc, Lm), enables more natural and smooth gradations and beautiful prints without graininess.

* Head configuration is selectable at the time of installation, and later modification is also possible. Our service personnel perform such modifications.

| Head arrangement | Color set | Features |

|---|---|---|

| 6 + 2 stagger | 6C + 2SP | High-quality printing with two spot colors added to the 6 colors C, M, Y, K, Lc and Lm. |

| 4 + 4 stagger | 4C + 4C | High volume production with high speed printing due to doubling the four colors C, M, Y and K. |

| 4 + 4 stagger | 4C + 4SP | Four colors C, M, Y and K as well as four spot colors enhance functionality and expressiveness. |

Color Gloss Function - Glossy texture realized without using a clear ink!

Equipped with a color gloss function that realize glossy colors with color inks alone. Realize impressive textures different from those of conventional clear inks. Realize impressive textures different from those of conventional clear inks. When exposed to ultraviolet radiation, high ink-density portions become hardened to a glossy tone, and low ink-density portions become hardened to a mat tone.

Unlike convetional clear ink printing, a just one time printing is very effective.

* Depending on the media and data, an adequate effect may not be possible, so carry out test printing in advance.

High-definition printing - 1800 dpi maximum, MFD2

The new 1800x1800 dpi mode is even better than the 1200x1200 dpi mode of the previous model. It is capable of beautifully and accurately reproducing images such as miniature paintings and tiny text.

In addition, "MFD2" which controls the position of the dots, delivers beautiful image quality with reduced graininess and color irregularities.

Ink landing system: 1800 dpi maximum

Strengthened structure of the printer body reduces shaking during printing, allowing ink droplets ejected from the print head to land in more precise positions. This provides for sharp edges and fine lines, and less color irregularities in solid printing.

Ball screw mechanism: Mechanical structure for high-precision printing

Ball screw

To reduce vibration during printing, the 7151 Series has been modified by having the print table move during printing and installing a fixed Y-bar. Two ball screws have also been added to both sides of the table to assist with its movement.

Furthermore, the UJF-7151 plusII uses a ball screw system for the Z-axis as well, which greatly increases the load capacity from 10 kg to 30 kg, making it possible to use heavy media and high-precision jigs for industrial applications.

Improved image quality by supporting MFD2 (Mimaki Fine Diffusion 2)

Supports MFD2 (Mimaki Fine Diffusion 2) for improved image quality. MFD2 controls the position of the dots to reduce graininess, suppress unintended noise and color irregularities, and enable beautiful prints.

Patent number / JPN: 7152323

Mimaki Advanced pass System 4 (MAPS4)

Generally, swath boundaries are straight lines. Therefore, a slight misalignment between boundaries causes banding or uneven color printing. MAPS4 reduces banding and uneven color printing with blurred boundaries similar to gradation printing.

■MAPS4 applied

Banding and uneven color printing are reduced by scattering swath boundaries. Beautiful print image is obtained.

■No MAPS4

Bandings appear on swath boundaries. Print quality is remarkably degraded because banding is recognizable on each boundary.

Reliable operating support package

Ink and media shortage, clogged nozzles, and other minor problems influence stable productivity.

The UJF-7151 plusII fully supports continuous printing with reliable technologies.

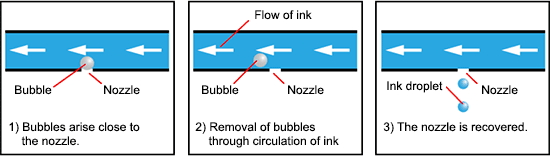

Printhead ink-circulation system reduces clogging nozzles

The ink-circulation system in the head reduces ink settling and thus provides stable ink jetting. In addition, this system removes air bubbles, which plug the nozzle.. Thanks to this function, the nozzle-cleaning frequency is reduced, and accordingly, cost-effective stable printing is achieved.

Head Comparison

Self-recovery

NCU automatically detects and recovers clogged nozzles

Clogged nozzles are detected automatically by monitoring ink droplets with sensors. When clogged nozzles are located, these are automatically cleaned, reducing waste printing. Nozzles are checked per transfer file.

NRS for maintaining productivity

If the clogged nozzles are not recovered after cleaning through the NCU function, the NRS selects substitute nozzles and then restarts printing. This is a significant novelty, since previously, when nozzle cleaning fails, the printhead has to be repaired by a technician, and the printing operation ceases until the printhead is repaired. The NRS* allows the printer to continue printing without interruption by using non-defective nozzles as substitutes for defective nozzles until the technician arrives.*

*NRS may not be activated depending on print modes.

Highly functional inks realize a variety of expressive effects and printing stability

Metallic

The MMC (Mimaki Metallic Control) is the system dedicated to metallic printing using Mimaki's unique "Surface Imaging technology". The MMC printing technology that separately prints one type of metallic ink in gloss and matte tones.

Using separately the beautiful glossy tone print like mirror finish and the matte tone print of metallic texture with suppressed gloss feeling will expand the range of expressions. Texture expression with embossing effect can be printed by changing the inkjet concentration. The texture expression whose appearance changes according to the light reflection provides a higher level of performance appeal. Color metallic expression is possible by printing with colored ink on top of metallic ink. By combining the application of metallic, color and color metallic, high-quality design print can be available.

White

Printing with high-concentration white ink as the basic color on transparent or deep-color media makes full-color images more vivid.

Clear

It is a clear ink that can give an additional value such as both gloss and matte tones, texture expression according to the application. UJF-7151 plusII mounting system for clear print control, " MCC (Mimaki Clear Control)" allows the minimization of uncured time to prevent dust from sticking and to avoid bubble generating. It provides high-grade glossy representation and expressive embossing feeling with highly-concentrated clear to lead a fine and beautiful texture print.

Primer

It is an inkjet primer that improves the adhesion of materials such as resin, glass, metal and those surface-finished.

Expanding the range of material selection, high value added applications can be produced.

As the primer, PR-200 is applied simultaneously with color printing, the PR-200 applying only to the necessary part of material is possible, too.

Therefore the texture of the base material that was lost by conventional manual primer applying can be maintained.

Patent number / JPN: 5817059 USA: US9,132,685 B2

Connected digital printing

Supports MDL (Mimaki Device Language) commands to automate the printing process

Mimaki offers command sets to enable customer production systems and peripheral devices to control our printers. Through applying these commands, the position and height of the media setting table, the start of printing, and other printer operations can be controlled. It also allows for the acquisition of remaining ink level and error information from the printer.

Regarding the MDL command, customers are able to build systems optimized to their individual applications by developing the necessary software using technical information (SDK) provided from Mimaki. The system will contribute to automation and labor saving in customers business.

UJF-7151 plusII Catalog (1.86MB)

Model

| UJF-7151 plusII | Maximum print area: 710 x 510 mm (28 x 20") |

|---|

Corresponding Ink

Application list

- Industrial Print

- Package

- Cylindrical Print

Application

- HeadphonesApplication

- New business in the age of the New NormalApplication

- Cooler Application

- Ema (Votive pictures are hung in shrines in Japan.) and Amulet goods Application

- Package for transportApplication

- ChopsticksApplication

- Earphone casesApplication

- ToothbrushApplication

- Fishing lureApplication

- Wood materialApplication

- Plug cover plateApplication

- Battery chargerApplication

- KeyboardApplication

- SD cardApplication

- CanApplication

- Wheel coverApplication

- Wristwatch bandApplication

- SkateboardApplication

- ToolApplication

- ContainerApplication

- Ballpoint penApplication

- StationeryApplication

- Welcoming BoardApplication

- [How to] MagnetApplication

- Acrylic standApplication

- CafeApplication

- HotelApplication

- Japanese‐style room interiorApplication

- Team store(Football)Application

- Local specialty storeApplication

- BottleApplication

- ThermosApplication

- [How to] Easy name printingApplication

- [How to] Original label printingApplication

- SealApplication

- Digital Foiling on Smartphone caseApplication

- Digital MAKIE on Smartrphone caseApplication

- Doming on Smartphone caseApplication

- Digital UV Dyeing on TPU smartphone caseApplication

- Custom smartphone caseApplication

- Shifting from Screen printing to UV inkjet printingSolution

- KEBAB (360-degree printing)Value-added Print

- Digital Foiling Value-added Print

- Digital MAKIEValue-added Print

- DomingValue-added Print

- Digital UV DyeingValue-added Print

- Digital UV Foil Transfer PrintingValue-added Print